Your glass cutter glides across the pane but leaves no score line, requiring multiple passes that crack your project into useless shards. Whether replacing a window or crafting stained glass art, a malfunctioning glass cutter transforms simple tasks into expensive disasters. When your glass cutter not working properly, you waste valuable materials and hours of work—until now. This guide delivers immediate, proven solutions for every failure mode so you can achieve clean, predictable cuts starting with your very next project.

Diagnose Your Glass Cutter’s Failure Symptoms

Why Your Cutter Leaves No Visible Score Line

When your wheel rolls across glass but creates no mark, three critical issues are likely at play. First, test your wheel’s sharpness by holding it at 30 degrees under bright light—a sharp carbide wheel reflects as a thin, continuous line, while a dull one appears rounded or chipped. Replace carbide wheels after 500-2,000 linear feet of cutting; diamond wheels typically last 10,000-50,000 feet before needing replacement.

Pressure matters more than you think. Apply 2-5 pounds downward force—about the pressure needed to lightly dent a tennis ball. Too little pressure creates no score; too much causes instant cracks. Practice on scrap glass until you hear a soft hiss rather than a grinding sound. Surface contamination also sabotages scoring—wipe glass with isopropyl alcohol after standard glass cleaner, then wait two minutes for complete drying. Alcohol residue repels the wheel, preventing proper scoring.

Recognize Problematic Score Line Characteristics

Incomplete or chipped score lines reveal technique flaws that compromise your entire project. Gapped scores indicate inconsistent pressure during cutting—support your elbow against your body to maintain steady force throughout the cut. White, powdery scores signal excessive pressure; reduce downward force immediately and verify wheel sharpness, as dull wheels require more pressure that creates weak, deep scores prone to shattering.

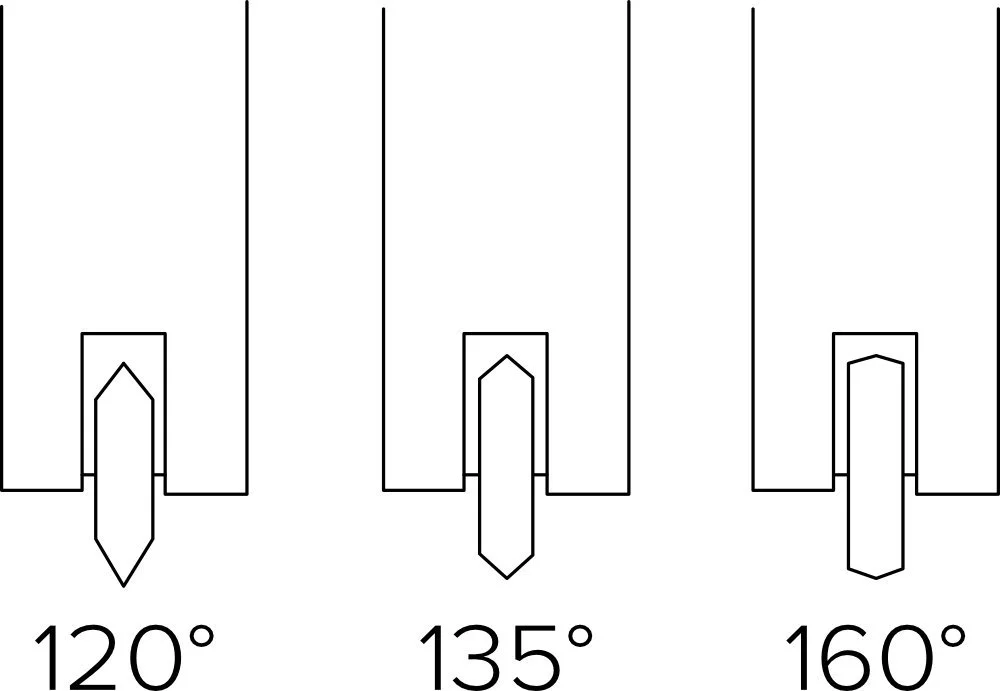

Chips along your score line mean either a damaged wheel or incorrect cutting angle. Inspect the wheel edge for nicks using a magnifying glass—replace the wheel if the edge radius exceeds 0.001″ (0.025mm). Even minor damage creates weak points where glass fractures unpredictably during separation. Professional glaziers keep multiple spare wheels on hand to avoid project delays when cutting performance declines.

Replace Dull Wheels and Restore Oil Systems

Install the Correct Replacement Wheel

Replacing your cutting wheel properly makes the difference between success and shattered glass. Start by removing the retaining screw with the exact screwdriver size specified for your model—using the wrong size strips the screw head, creating a new problem. Note the wheel’s orientation before removal, as installing it backward causes immediate failure.

Clean the axle thoroughly with an alcohol-soaked cotton swab to remove glass dust that interferes with proper rotation. Install your new wheel matching diameter to glass thickness: 1/8″ wheels for 1/8″-1/4″ glass, 3/16″ wheels for 1/4″-3/8″ glass, and 1/4″ wheels for 3/8″-1/2″ glass. Tighten the screw to 2-3 inch-pounds—snug enough to prevent wobble but not so tight you strip the threads. Complete the process by making 5-10 practice cuts on scrap glass to break in your new wheel before attempting critical projects.

Revive Oil-Fed Cutter Performance

Dry oil reservoirs cause wheel squeaking, multiple passes, and scores that won’t separate cleanly. Refill to 75% capacity using SAE 10 light machine oil—never automotive oil, which contains detergents that gum the wheel mechanism. After filling, hold your cutter vertically; oil should reach the wheel within 10 seconds for proper lubrication.

Clogged oil channels require immediate attention. Submerge the cutter tip in isopropyl alcohol and insert a thin wire into the oil channel while gently working it back and forth. Continue flushing until the alcohol runs clear, indicating all debris has been removed. Test oil flow before cutting by holding the cutter vertically for 15 seconds—visible oil at the wheel contact point confirms proper function.

Perfect Your Cutting Technique in Minutes

Apply Precise Pressure by Glass Thickness

Your downward pressure must match glass thickness exactly. For 1/8″ (3mm) glass, use 1-2 pounds of pressure—light fingertip pressure that creates a soft hiss. At 1/4″ (6mm), increase to 2-3 pounds with firm grip pressure. When cutting 3/8″ (10mm) glass, apply 3-4 pounds using full hand pressure. For 1/2″ (12mm) glass, use 4-5 pounds of pressure while leaning slightly into the cut.

Build muscle memory by practicing pressure application on a bathroom scale. Place your cutter on the scale and practice applying your target pressure while maintaining smooth motion. Consistent pressure prevents the wandering lines and incomplete scores that waste expensive glass. Professional glaziers recommend this drill for 5 minutes before every cutting session to maintain precision.

Maintain Perfect 90-Degree Cutting Angle

Angle errors cause chipping and wandering lines that ruin precision work. Verify your 90-degree angle by cutting a test line on scrap glass, then placing a straightedge along the score. Any gap between the straightedge and score reveals angle errors that must be corrected. Use your shoulder as a pivot point rather than your wrist—lock your elbow and move your entire arm for consistent angle control.

Practice against a straight board guide until the motion feels natural. When cutting large pieces, mark reference points every 6 inches along your cutting line to help maintain consistent alignment. The best glaziers develop an internal sense of proper angle through daily practice on scrap glass, making perfect cuts second nature.

Optimize Glass Preparation and Workspace Setup

Clean and Support Glass Like a Professional

Professional results require meticulous surface preparation. Start with standard glass cleaner to remove dust and fingerprints, then follow with an isopropyl alcohol wipe to eliminate oils that repel the cutting wheel. Allow two minutes of air drying time—rushing this step leaves alcohol residue that prevents proper scoring.

Your glass support system is equally critical. Place carpet squares or foam padding under the entire cutting path to prevent flexing. Verify full support by placing a straightedge along the cutting line—no light should show beneath it. Gaps in support cause glass flexing that creates uneven scores and unexpected breakage during separation.

Handle Special Glass Types Correctly

Tempered glass requires special handling—you cannot cut it after tempering. Look for etched markings or distortion patterns that identify tempered glass. Attempting to cut tempered glass causes explosive shattering into small cubes—always order pre-cut pieces instead. For coated glass like Low-E varieties, remove a 1/8″ strip of coating along your intended cut line using a carbide scribe before wheel cutting.

Thick glass demands matching wheel diameter—undersized wheels skate over thick glass, creating shallow scores that won’t separate. Verify wheel specifications match your glass thickness before starting. Cold glass requires less pressure than warm glass; let material acclimate to your workspace temperature for 30 minutes before cutting to prevent unexpected cracking.

Validate Repairs and Prevent Future Failures

Test Cutting Performance Systematically

Verify your fixes with a 6-inch test cut on scrap glass matching your project material. A proper score appears as a uniform white line without chips, with depth at 10-20% of glass thickness. Attempt separation—clean breaks indicate success; rough edges mean you need to adjust technique. Track three critical metrics: pressure consistency, cutting speed (2-4 inches per second), and angle maintenance.

When troubleshooting persistent issues, follow this sequence: check wheel sharpness first, then verify pressure application, then examine glass support. Most glass cutter not working problems stem from these three factors rather than complex mechanical failures. Keep a maintenance log noting wheel replacements, oil refills, and successful cutting parameters for different glass types.

Implement Daily Maintenance That Prevents Failures

Prevent future glass cutter not working episodes with a simple daily routine. After each use, blow out glass dust with compressed air and wipe the cutter with an alcohol pad. Store your tool in a protective case—never loose in your toolbox where impacts damage the precision wheel. Weekly checks should include wheel sharpness verification, oil flow testing for oil-fed models, handle integrity inspection, and pressure calibration on a scale.

Build muscle memory through dedicated practice—spend 15 minutes weekly on scrap glass focusing on one element per session: pressure control one day, cutting speed the next, then angle maintenance. Maintain your workspace temperature between 65-75°F, as extreme temperatures alter glass properties and affect cutting performance. Professional glaziers track their successful cutting parameters for different glass types, creating a reference guide that prevents future failures.

Key takeaway: A malfunctioning glass cutter fails from three root causes—dull wheel, wrong technique, or poor setup. Fix the wheel first, then perfect your technique, finally optimize your workspace. Master these elements and every cut breaks cleanly, saving glass, time, and frustration. Track your successful parameters for different glass types and maintain your cutter daily—these simple habits transform unreliable cutting into precise, predictable results every time.