Picture slicing through a 6-inch steel plate with the same ease as cutting foam—no sparks, no melting, and the metal stays cool enough to touch. This isn’t science fiction; it’s the daily reality of water jet cutters. These machines transform ordinary water into a supersonic cutting tool capable of machining titanium for spacecraft or delicate glass artwork with equal precision. Unlike lasers or plasma cutters, water jets leave zero heat damage, making them indispensable for aerospace, automotive, and artistic applications where material integrity is non-negotiable. By the end of this guide, you’ll understand exactly how these systems convert water pressure into a Mach 3 cutting beam, why garnet sand turns water into a metal-slicing force, and how operators achieve micron-level accuracy on everything from rubber gaskets to bulletproof glass.

Supersonic Physics Behind Water Jet Cutting

Water jet cutters bypass thermal limitations by harnessing pure kinetic energy. Standard systems pressurize water to 30,000–100,000 psi—that’s 400–6,700 times your car tire pressure. When this hyper-compressed water blasts through a jewel orifice just 0.003–0.015 inches wide (thinner than a human hair), it accelerates to 2,500–2,700 feet per second. This equals Mach 3, three times the speed of sound. At these velocities, water transforms from a liquid into a coherent, needle-thin beam capable of micro-erosion—stripping material away grain by grain without heat transfer.

Pure Water vs. Abrasive Jet Cutting: When to Use Each

Pure water jets rely solely on hydraulic force, making them ideal for soft materials where contamination or heat is unacceptable. You’ll see these slicing:

– 24-inch foam insulation blocks for construction

– Sanitary food products like frozen cakes or cheese wheels

– Rubber gaskets and paper products without fraying

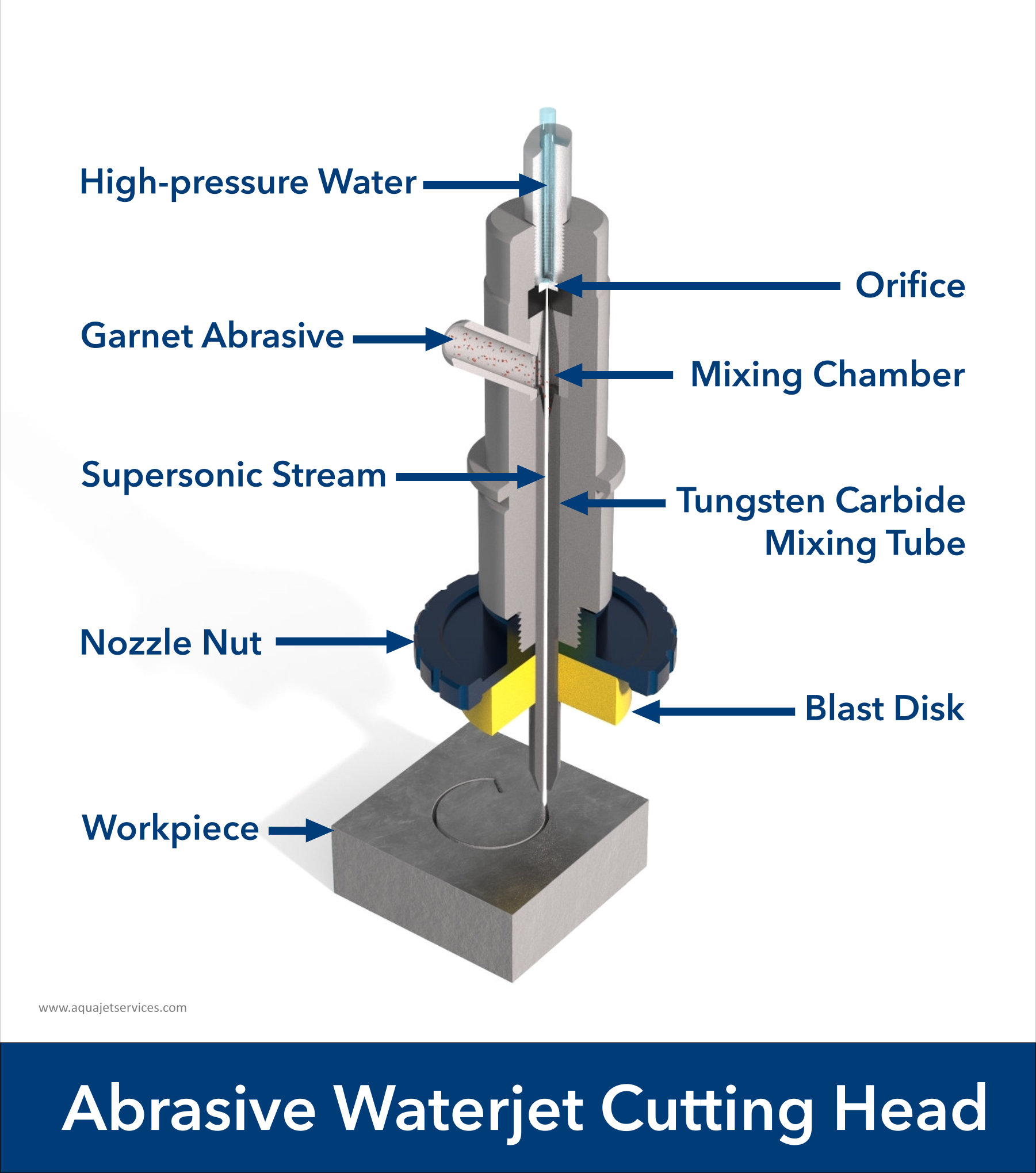

Abrasive water jets inject garnet sand into the stream, multiplying cutting power for hard materials. Here’s why it works: The venturi effect in the mixing chamber sucks abrasive particles (0.3–1.5 lbs per minute) into the water beam. Inside the tungsten-carbide mixing tube, these grains accelerate to 80–90% of water velocity (≈2,200 ft/s). The resulting slurry cuts through:

– 12-inch steel plates for shipbuilding

– Titanium aerospace components

– Granite countertops and bulletproof glass

Pro Tip: Always use pure water for food or rubber to avoid contamination. Switch to abrasive jets only when tackling metals, stone, or ceramics.

Critical Components That Make Water Jet Cutting Possible

Every system follows a precise water-to-cut journey. Understanding these parts reveals why water jets outperform thermal cutters.

How High-Pressure Pumps Generate Mach 3 Speeds

Intensifier pumps dominate industrial setups. Hydraulic oil drives a piston that compresses water through a tiny plunger, achieving >60,000 psi quietly and efficiently. They’re ideal for aerospace applications requiring extreme pressure stability. Direct-drive pumps use motor-driven crankshafts (like car engines) for ≤60,000 psi jobs. Cheaper to maintain, they’re common in stone-cutting workshops but noisier during operation. Both systems lose ~14% water volume at 90,000 psi due to compression, while friction heats the water by 30°F—requiring chillers to maintain cutting consistency.

Why Jewel Orifices and Mixing Tubes Dictate Cut Quality

The jewel orifice (synthetic diamond, ruby, or sapphire) forms the initial coherent beam. Laser-drilled to micron precision, it lasts 200–800 hours but costs $20–150—making water filtration critical. In abrasive systems, the mixing tube (3–4 inches of tungsten-carbide composite) accelerates garnet to cutting speed. This component wears fastest—lasting just 40–120 hours at $60–200 per replacement. Critical insight: Using crushed garnet instead of alluvial garnet boosts cutting speed 10–20% but doubles mixing tube wear.

Step-by-Step Material Removal Process

Water Conditioning: The Hidden Key to System Longevity

Municipal water filtered to <1 ppm total dissolved solids prevents nozzle clogging. A chiller maintains 60–70°F supply temperature—extending high-pressure seal life from 500 to 1,500 hours. Skipping this step risks $300–800 in premature seal replacements.

Piercing Techniques That Prevent Material Damage

High-pressure piercing (60–90 kpsi with continuous abrasive) blasts through 1-inch steel in 0.5–3 seconds but shatters tempered glass. For brittle materials like stone or composites:

1. Start at 10–15 kpsi with pre-loaded abrasive

2. Pierce gently to avoid shock cracks

3. Ramp pressure up after initial breakthrough

Modern systems use dynamic piercing software to auto-adjust pressure for carbon fiber laminates—preventing delamination in aircraft parts.

Abrasive Selection: Speed vs. Cost Tradeoffs

Garnet mesh size directly controls cut quality and speed:

– 50–60 mesh: Fastest cuts (ideal for structural steel), but rough edges (Q1 finish)

– 80–120 mesh: Best balance for most jobs—smooth edges at 70% of max speed

– 150–220 mesh: Mirror-like Q5 finishes for medical implants, but cuts 6× slower

Expert note: Aluminum oxide boosts ceramic cutting speed 30% but erodes mixing tubes 100× faster—only cost-effective for high-margin aerospace work.

5-Axis Precision: Beyond Flat Cutting

Water jet heads move on five axes:

– X/Y (horizontal plane)

– Z (vertical standoff distance)

– A (tilt angle up to 90°)

– C (rotation around Z-axis)

This enables bevel cuts for weld prep and 3D contours impossible with lasers. Custom controllers compensate for stream lag (the jet’s slight curve during direction changes) by slowing the head at corners—achieving ±0.001″ repeatability. For taper-free cuts, operators tilt the head to offset kerf angle into waste material.

Material Limits: What Water Jets Can’t Cut

Despite cutting 18-inch steel in specialized setups, water jets fail on:

– Tempered glass (shatters from internal stress)

– Diamond (harder than garnet abrasive)

– Ceramics >8.5 Mohs hardness (requires diamond abrasives)

Critical warning: Never attempt tempered glass—fragments can eject at dangerous speeds.

Why Water Jets Beat Lasers and Plasma Cutters

Zero Heat Damage Preserves Material Integrity

Unlike thermal methods, water jets produce no heat-affected zone (HAZ). This prevents:

– Warping in thin aluminum sheets

– Loss of temper in hardened steel

– Micro-cracks in titanium aerospace parts

Minimal Force Enables Delicate Work

With <5 pounds of downward force, water jets cut:

– 0.001-inch copper foil without distortion

– Multi-layer circuit boards without delamination

– Food products without crushing

Eco-Friendly Operation

Closed-loop water recycling cuts waste by 90%, while spent garnet is non-toxic and landfill-safe. Compare this to plasma cutting’s toxic fumes or laser’s nitrogen consumption.

Daily Maintenance That Prevents Costly Downtime

Neglecting these steps risks $500+ in emergency repairs:

– Daily: Inspect jewel orifice for chips; verify Z-axis standoff

– Weekly: Replace water filters; drain/clean 3-foot-deep catcher tank

– Monthly: Rebuild high-pressure check valves; test safety relief valves

Pro Tip: Track mixing tube hours religiously. A worn tube increases kerf width by 0.005 inches, ruining tight-tolerance parts.

Water jet cutters prove that sometimes the simplest solutions—water, pressure, and grit—are the most revolutionary. By leveraging supersonic physics instead of heat, they cut through material limitations that stymie traditional methods. Whether you’re fabricating jet engine components or custom kitchen countertops, mastering pressure control, abrasive selection, and piercing techniques unlocks this technology’s full potential. Remember: the right mesh size for your material, combined with precise CNC motion control, turns water into the ultimate cold-cutting tool. Start with 80–120 mesh garnet and 60 kpsi for most metals, then refine based on your cut quality needs—your materials will stay stress-free, cool, and ready for precision assembly.