That new Ryobi brush cutter box sitting in your garage won’t clear your overgrown property by itself. Most homeowners spend 30-45 minutes assembling their Ryobi brush cutter correctly, but skipping steps can lead to dangerous wobble, poor performance, or even equipment failure during operation. This comprehensive guide shows exactly how to assemble Ryobi brush cutter models safely and efficiently, whether you’ve purchased a straight-shaft or curved-shaft version. You’ll learn professional techniques most manuals overlook, ensuring your tool performs reliably season after season.

Before you start, gather your patience and basic tools—you’re about to transform those boxed components into a powerful yard-clearing machine. Follow these steps precisely, and you’ll avoid common pitfalls that send many first-time users back to the store for replacement parts or, worse, create safety hazards during operation.

Identify Your Ryobi Brush Cutter Components Correctly

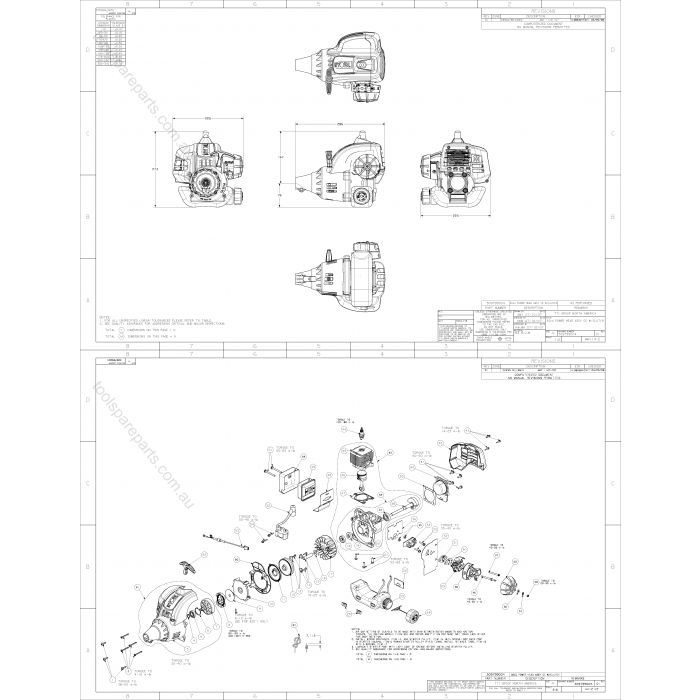

Lay out all parts on a clean, well-lit workspace before beginning assembly. Your Ryobi brush cutter box contains specific components depending on whether you purchased a straight-shaft or curved-shaft model. Check every piece against the manual’s parts diagram—missing even a single washer creates dangerous vibration during operation.

Straight shaft models contain these essential components:

– Main drive shaft with clutch housing

– Loop handle assembly with clamp mechanism

– J-handle throttle control unit

– Tri-arc blade or bump-feed string head

– Full-size safety guard with mounting hardware

Curved shaft models include these specific parts:

– Pre-assembled curved drive shaft

– Single loop handle with direct bolt mount

– String head already attached to shaft

– Compact guard assembly designed for curved operation

Before proceeding, verify you have all required hardware from the small parts bag. Most Ryobi models include multiple washers, specialized nuts, and bolts that look similar but serve different purposes. Sorting these components now prevents frustrating mid-assembly confusion.

Prepare Your Workspace and Essential Tools

Clear a 6×6 foot area in your garage or driveway with good lighting. Concrete works best as it prevents small parts from rolling away. Critical safety step: Put on safety glasses before opening the box—metal burrs on new parts can cause eye injuries during assembly.

You’ll need these specific tools:

– Ryobi T-wrench (included in hardware bag)

– Phillips screwdriver (#2 size)

– Adjustable wrench (8-10 inch)

– Clean work towel (prevents scratches)

– Small container for hardware sorting

Pro assembly tip: Place a non-slip mat under your workspace. This catches falling hardware and prevents damage to polished shaft components. Keep children and pets away during assembly—those small parts present choking hazards and could interfere with your concentration.

Secure the Handle Assembly Properly

The handle installation differs significantly between straight and curved shaft models. Incorrect handle positioning causes rapid fatigue and poor control during operation.

Position Loop Handle for Optimal Comfort

Slide the loop handle onto the shaft approximately 12-16 inches from the throttle control. The handle should angle slightly upward for natural grip positioning. Critical ergonomic check: Stand naturally with arms at 45-degree angle—your forward hand should meet the handle without reaching or hunching.

For curved shaft models, bolt the handle directly to the mounting plate using the included hardware. These models have fixed handle positions, so ensure the handle faces the correct direction before tightening bolts completely.

Install J-Handle Throttle Control Correctly

Straight shaft models require attaching the J-handle throttle unit. The trigger mechanism must face toward the rear when properly installed—this allows natural thumb operation during use. Common dangerous mistake: Mounting the J-handle upside down creates awkward operation and potential safety hazards.

Follow this bolt sequence:

1. Finger-tighten top bolt to establish position

2. Align handle parallel to the shaft

3. Tighten bottom bolt firmly with T-wrench

4. Complete top bolt tightening to secure position

After installation, test the throttle movement—full range should feel smooth without binding.

Mount the Cutting Guard for Maximum Safety

The safety guard protects you from flying debris and must be installed before attaching any cutting head. Incorrect guard positioning creates dangerous vibration patterns and reduces cutting efficiency.

Align Guard for Proper Operation

For string heads, the guard’s trimmer line cutter must face forward (away from operator). Metal blade guards feature a directional arrow showing proper rotation. Critical safety point: The guard’s edge should extend 1-2 inches beyond the maximum cutting swath to contain debris effectively.

Follow these mounting steps:

– Remove protective nut from shaft end

– Slide guard over shaft threads carefully

– Align bolt holes precisely with shaft housing

– Insert mounting bolts and tighten in star pattern

After installation, spin the guard by hand—any resistance indicates misalignment that must be corrected before proceeding.

Connect Your Cutting Attachment Securely

Ryobi brush cutters accept both string heads and metal blades, but installation techniques differ significantly. Always perform this step with the unit on a stable surface, engine side down.

Install String Head Without Damaging Clutch

Thread the string head clockwise onto the shaft. Most Ryobi models use reverse threading—turning left (counterclockwise) actually tightens the head. Listen for the audible click indicating proper seating in the clutch mechanism. Hand-tighten only; over-torquing with tools damages the clutch permanently.

Quick verification test: Pull the string gently—if the head spins freely without wobble, it’s secured correctly. If it feels loose or binds, remove and reinstall.

Attach Metal Blade Safely

Blade installation requires the included washer and reverse-thread nut. The blade’s cutting edges must face away from the guard when mounted properly. Critical safety note: Always wear cut-resistant gloves—new blades arrive razor-sharp.

Follow this exact sequence:

1. Place washer on shaft with beveled edge outward

2. Position blade with teeth pointing away from guard

3. Thread reverse nut counterclockwise by hand

4. Tighten with T-wrench until snug (do not over-tighten)

After installation, verify blade rotation direction matches the arrow on the guard—reversed blades cut inefficiently and create dangerous kickback.

Optimize Handle Position for Comfort

Stand naturally with the assembled cutter at your side. The loop handle should align with your hip bone, allowing comfortable operation without bending or reaching. Pro technique: Mark your optimal position with painter’s tape before final tightening.

Perform this comfort test: Practice the sweeping motion used in trimming vegetation. Adjust handle position until the motion feels natural and balanced. Proper positioning reduces fatigue by 40% during extended use sessions.

Complete Essential Safety Verification

Before first use, verify every connection point. Vibrations during operation can loosen improperly secured components within minutes.

Check Critical Connection Points

Verify these components:

– Handle clamp bolts (shouldn’t rotate when tested by hand)

– Guard mounting bolts (firm resistance when turned)

– Cutting head attachment (no wobble when gently pulled)

– Throttle cable routing (no kinks or pinching)

Warning: Loose components create dangerous vibration patterns that can cause loss of control during operation.

Inspect Cables and Lines Thoroughly

Ensure throttle cable moves smoothly from idle to full throttle position. For gas models, verify fuel lines have gentle curves without sharp bends. Critical hazard: Pinched fuel lines cause poor performance and potential fire hazards from fuel leaks.

Install Battery or Prepare Fuel Properly

For 40V battery models, skip fuel preparation. Gas units require proper fuel mixture before operation.

Battery installation steps:

– Slide battery into rear housing with firm push

– Listen for double-click confirming proper seating

– Perform lock test: Tug gently—it shouldn’t release

– Verify battery is fully charged before first use

For gas models:

– Mix 50:1 gas-to-oil ratio (2.6 oz oil per gallon)

– Use only fresh, unleaded gasoline

– Fill tank to 80% capacity to allow expansion

– Wipe all spills immediately before starting

Test Your Assembly Before First Use

Perform these critical tests in a safe, open area before tackling overgrown vegetation:

Pre-operation checklist:

– Engine starts and idles smoothly (gas models)

– Throttle response is immediate and smooth

– Cutting head spins without wobble

– Safety switch functions properly

– No unusual vibrations or noises

First use protocol: Operate at low speed for 5 minutes to confirm all components seat properly. Turn off, allow to cool, then recheck all bolt tightness before serious work.

Avoid These Common Assembly Mistakes

Even experienced users make these critical errors. Double-check your work against this list before operation:

- Handle positioned too low: Causes immediate back strain

- Guard installed backward: Creates dangerous debris spray pattern

- Blade mounted with teeth inward: Reduces cutting efficiency by 50%

- Over-tightened cutting head: Permanently strips clutch threads

- Skipped cable inspection: Leads to sudden power loss during use

Establish Proper Maintenance Routine

Your first month of use determines long-term reliability. Follow this maintenance schedule:

Week 1: Recheck all bolts daily—they loosen as components seat

Week 2: Clean air filter (gas models) after every 5 hours use

Week 3: Inspect string head for wear—replace before damage occurs

Week 4: Lubricate shaft at connection points as specified in manual

Pro storage tip: Hang vertically with cutting head up to prevent oil seepage in gas models during storage.

Your Ryobi brush cutter is now properly assembled and safety-checked, ready to tackle overgrown brush and stubborn weeds. Remember that slow, controlled movements produce cleaner cuts and reduce operator fatigue compared to aggressive slashing. Start with light trimming tasks to perfect your technique before attempting dense vegetation. Proper assembly ensures years of reliable service—recheck critical connections after every 5 hours of use to maintain peak performance and safety. Now get out there and reclaim your yard with confidence!