Locked out of your storage unit with a stubborn padlock? Struggling to remove rusted bolts on a DIY project? Knowing how to use a bolt cutter properly transforms this powerful tool from a potential hazard into your go-to solution for metal obstacles. Unlike bolt cutters you might see in movies, real-world cutting requires precise technique—not brute force—to slice through hardened steel without damaging the tool or risking injury. This guide reveals the exact methods professionals use to cut padlocks, chains, and bolts safely while extending your cutter’s lifespan. You’ll learn to match cutter size to material, execute flawless cuts, and troubleshoot failures—all while avoiding the top mistakes that cause 70% of bolt cutter accidents.

Whether you’re a homeowner tackling an emergency lock removal or a contractor preparing for job-site challenges, mastering how to use a bolt cutter saves costly service calls and prevents dangerous mishaps. We’ll skip generic theory and dive straight into actionable steps—from inspecting blades to positioning your body—that turn frustrating struggles into clean, one-motion cuts. By the end, you’ll confidently handle everything from delicate padlock removals to industrial-grade chain cutting.

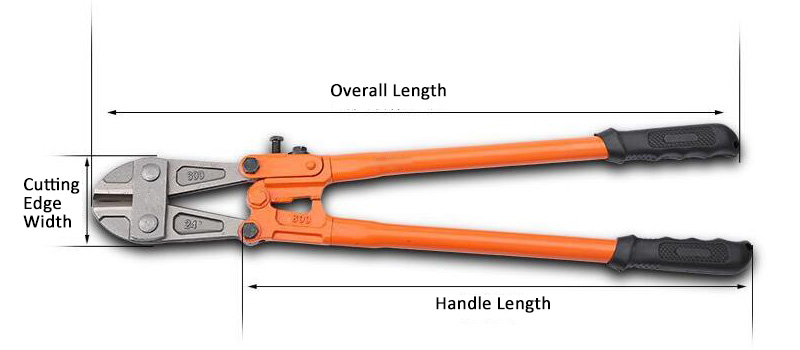

Match Your Bolt Cutter to Material Thickness

Choosing the wrong size cutter guarantees failure. Oversized tools strain your back; undersized ones bend handles or shatter blades. Always match your cutter’s capacity to the material’s hardness and thickness using these verified specifications:

- 8-14 inch cutters: Soft metals (copper, aluminum) up to 3/16 inch; hardened steel up to 1/8 inch

- 18-24 inch cutters: Soft metals up to 1/4 inch; hardened steel (padlocks, chains) up to 3/16 inch

- 30-36 inch cutters: Soft metals up to 5/16 inch; hardened steel up to 1/4 inch

- 42+ inch cutters: Soft metals up to 3/8 inch; hardened steel up to 5/16 inch

Identify Your Blade Type for Precision Cuts

Center-cut blades (straight jaws) crush bolts and rods cleanly but leave burrs. Clipper-cut blades (angled jaws) make flush cuts against walls or floors—essential for removing security chains without damaging surfaces. Shear-cut blades (scissor-action) prevent cable unraveling when cutting wire rope. Using the wrong blade type causes jagged edges or tool slippage. For example, never attempt padlock removal with shear-cut blades—they’ll spin the shackle instead of slicing it.

Gear Up with Essential Safety Equipment

Skipping safety gear turns routine cuts into emergencies. Metal shards travel at 400+ mph when hardened steel snaps, risking permanent eye damage. Your non-negotiable protection setup must include:

- ANSI-approved safety glasses: Wraparound style to block flying fragments from all angles

- Cut-resistant gloves: Level 5 ANSI rating to protect against sharp burrs

- Steel-toed boots: Prevent foot injuries from falling cut pieces

- Long sleeves/pants: Heavy cotton or denim to shield skin from sparks and shavings

Prepare Your Workspace Like a Pro

Clear a 6-foot radius around your cutting area—bystanders have been injured by ricocheting metal fragments. Elevate work to waist height using a bench or sawhorse; cutting while hunched over reduces leverage by 40% and strains your spine. Ensure bright, shadow-free lighting so you can spot hairline cracks in blades. Critical tip: Place a magnetized tray under the cut zone to catch sharp metal scraps—never let them accumulate on the ground.

Inspect Blades and Handles Before Every Cut

A 30-second inspection prevents catastrophic failures. Check these critical points before applying pressure:

- Blade condition: Run a finger along edges (carefully!) to detect chips or nicks—these cause uneven cuts and tool kickback

- Pivot tightness: Shake handles side-to-side; any wiggle means loose bolts that reduce cutting force

- Handle integrity: Look for hairline cracks near the pivot—bent handles snap under load

- Blade alignment: Close jaws fully; gaps indicate misalignment requiring professional adjustment

Pro warning: If blades don’t meet evenly across their entire length, stop immediately. Forcing a cut with misaligned jaws can shear the pivot bolt, sending handles flying toward your face.

Perfect Your Cutting Stance and Grip

Stance for Maximum Power and Safety

Plant feet shoulder-width apart with your dominant foot slightly forward. Bend knees 15 degrees (not your waist!) to transfer body weight into the cut. Position yourself so severed pieces fall away from your body—never toward your legs. For overhead cuts on ladders, brace your hip against the rung to prevent backward falls when the material snaps.

Power-Enhancing Grip Technique

Place hands at the very ends of the handles—this doubles leverage compared to gripping mid-handle. Wrap thumbs completely around the grips; extended thumbs get crushed during tough cuts. Squeeze handles with palms, not fingers, to avoid hand fatigue. Key insight: Apply steady pressure using your core muscles, not arm strength. Jerky motions waste 60% of your force and increase blade slippage risk.

Execute Flawless Cuts in Three Phases

Position Material in the Jaw’s Sweet Spot

Slide material into the deepest section of the jaws—closest to the pivot bolt. This “power zone” requires 70% less force than cutting near the jaw tips. Align the cut perpendicular to the material; angled cuts cause blade binding. For padlocks, target the shackle’s thinnest point near the lock body.

Apply Pressure Like a Blacksmith

Start with light pressure to seat the material firmly. Gradually increase force over 3-5 seconds, leaning your body weight into the handles. Complete the cut in one smooth motion—pausing mid-cut creates stress fractures in blades. When the material severs, release handles slowly to prevent dangerous kickback. Pro tip: For rusted bolts, tap the shank with a hammer first to break corrosion bonds—this reduces cutting force by half.

Cut Specific Materials Without Errors

Remove Padlocks Without Flying Debris

Support the lock body with your gloved non-cutting hand (fingers clear of blades!) to prevent spinning. Cut the shackle’s curved section—not the straight sides—for fastest penetration. Expect a loud snap; maintain grip until pieces separate fully. Critical: Never cut padlocks attached to gates—you’ll damage hinges.

Sever Chains Without Whipping Hazards

Identify the welded seam (weakest link) and position it so the cut faces away from you. Support 6+ inches of chain on both sides with pliers to prevent whipping. Cut only one link per operation—attempting multiple links distorts the chain and jams blades.

Slice Bolts with Zero Bend

Secure bolts in a vise below the cut line. Mark the cut point with a center punch to prevent blade slippage. Cut within 1/4 inch of the vise jaw for maximum stability. File sharp edges immediately after cutting using a deburring tool.

Fix Immediate Cutting Failures

When Blades Won’t Bite Through Metal

Stop after 3 failed attempts. Check if you’re cutting in the jaw’s power zone—90% of “impossible” cuts stem from tip-positioning errors. Verify material thickness against your cutter’s rating; hardened steel padlocks often exceed 1/8 inch capacity of mini-cutters. If blades are dull, apply penetrating oil to the cut line and reattempt—this lubricates the fracture point.

Repair Ragged or Incomplete Cuts

Rotate material 180 degrees and recut from the opposite side if blades chip. For persistent misalignment, tighten the pivot bolt 1/8 turn—most cutters have an adjustment screw. Replace blades showing visible nicks; sharpening hardened steel requires industrial equipment.

Maintain Your Cutter for Decades of Service

Daily Post-Cut Routine

Wipe blades with a dry microfiber cloth to remove metal shavings that accelerate rust. Apply 1-2 drops of 3-in-1 oil to the pivot point while working handles open/closed. Store vertically in a dry shed—never leave outdoors where humidity dulls blades overnight.

Quarterly Deep Maintenance

Disassemble the pivot bolt (if your model allows), clean grit with a brass brush, and re-lubricate with lithium grease. Check handle ferrules for looseness; tap them gently with a mallet if wobbling. Pro secret: Store blades coated in cosmoline during winter—it prevents oxidation better than oil.

Select Professional-Grade Cutters That Last

Spot Quality-Build Indicators

Choose chromium-molybdenum steel blades (not “high-carbon steel”) for true hardened-steel cutting. Tubular steel handles resist bending better than solid rods. Test pivot adjustability before buying—knurled bolts should tighten smoothly without stripping. Avoid cutters under $40; quality 24-inch models start at $65.

Final takeaways: Mastering how to use a bolt cutter hinges on three non-negotiables—matching cutter size to material, cutting in the jaw’s power zone, and wearing full safety gear. Always inspect blades before use, support material properly, and apply smooth pressure. Store your cutter dry and oiled after every job to prevent 95% of premature failures. For padlocks under 1/4 inch, a 24-inch center-cut model is your safest bet; tackle industrial chains with 36-inch hydraulic cutters. If blades chip or handles bend, retire the tool immediately—no cut is worth risking injury. Keep this guide handy, and you’ll conquer metal obstacles safely for years.