That frustrating moment when your rebar cutter jams halfway through a cut or produces jagged edges that won’t fit your formwork is all too familiar for DIYers and contractors alike. Knowing how to use a rebar cutter properly transforms what could be a dangerous, time-consuming chore into a precise, efficient part of your construction workflow. Most beginners underestimate the force required and the safety risks involved when cutting steel reinforcement bars.

Mastering rebar cutting techniques prevents wasted materials, reduces physical strain, and most importantly, keeps you safe from flying metal fragments. This guide delivers the exact methodology construction professionals rely on to cut rebar cleanly and safely—whether you’re reinforcing a concrete driveway or building a foundation for a new shed. You’ll discover how to select the right cutter for your project, execute perfect cuts every time, and maintain your tool to last through dozens of projects.

Select the Right Rebar Cutter for Your Project Size

Manual Cutters for Occasional Home Projects

Manual rebar cutters deliver surprising power without electricity or hydraulics, making them ideal for homeowners tackling small concrete projects. These heavy-duty tools handle rebar up to #5 (5/8 inch diameter) with proper technique—attempting larger sizes risks tool damage and injury. Position the rebar mark precisely in the deepest part of the cutting jaws, not near the tips where leverage fails. Apply steady, increasing pressure using your body weight rather than arm strength alone. Expect 15-30 seconds of effort per cut on standard #4 rebar. Never stand directly over the cutter—position yourself to the side in case the rebar snaps unexpectedly.

Electric Cutters for Medium to Large Construction Jobs

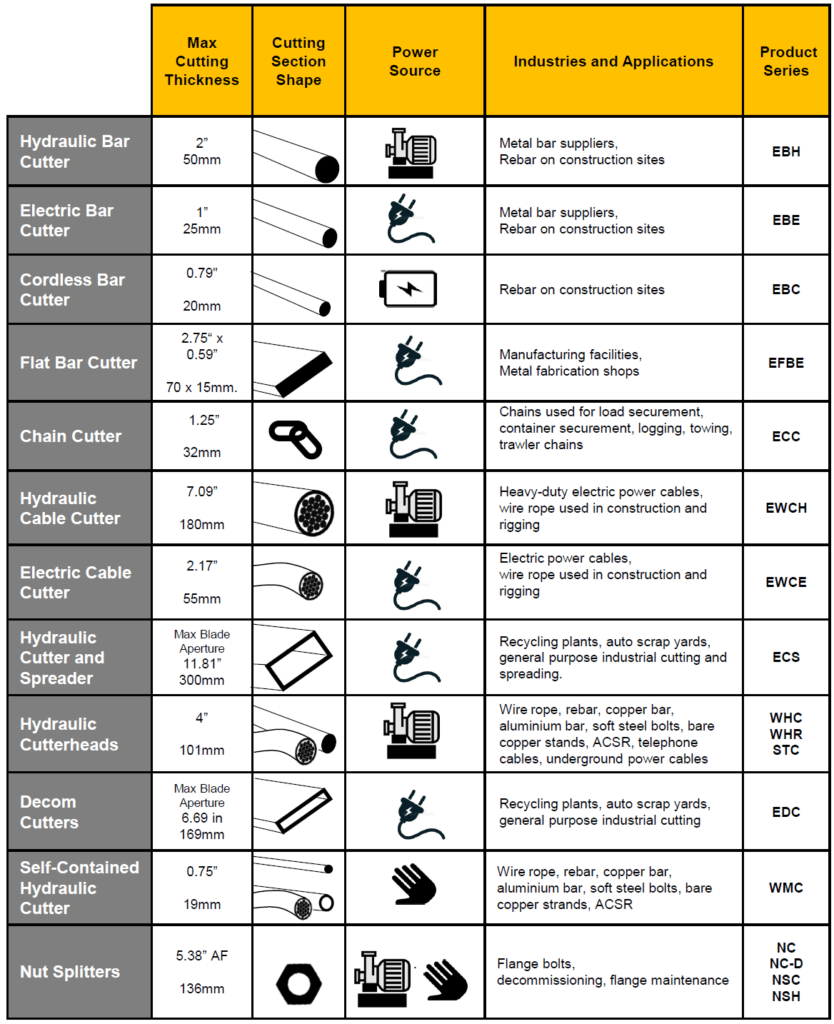

Electric rebar cutters save significant time on projects requiring dozens of cuts, slicing through #8 rebar (1 inch diameter) in under 5 seconds. Before operation, verify your outlet has GFCI protection—wet job sites demand this critical safety feature. Mark your cut line with soapstone for maximum visibility on oily rebar surfaces. Position the cutter’s guide fence against your mark, then squeeze the trigger smoothly without forcing the tool into the rebar. Allow the blade to reach full speed before contacting the steel. After cutting, wait for the blade to stop completely before setting the tool down—rushing this step causes accidental contact with the still-spinning blade.

Hydraulic Cutters for Commercial Construction Demands

Hydraulic rebar cutters handle the thickest reinforcement bars (#9 and larger) with minimal physical effort, but require significant setup. Check hydraulic fluid levels and connections before connecting the power unit—low fluid causes inconsistent cutting force. Position the rebar fully seated in the cutting head, ensuring it won’t shift during operation. Activate the pump slowly while monitoring the pressure gauge; most units require 10,000-15,000 PSI for clean cuts. Never exceed manufacturer pressure specifications—over-pressurizing damages seals and creates dangerous failure points. Release hydraulic pressure completely before removing cut pieces to prevent sudden movement.

Essential Safety Gear You Must Wear

Non-Negotiable Eye Protection Requirements

Flying metal fragments travel at dangerous speeds during rebar cutting—standard safety glasses provide insufficient protection. ANSI Z87.1-rated safety goggles with side shields form your first line of defense, while a face shield adds critical coverage for overhead cuts. Inspect your eye protection before each use for scratches or cracks that compromise safety. Replace scratched lenses immediately—impaired vision increases accident risk more than most workers realize.

Critical Hand and Body Protection

Heavy-duty leather gloves protect against sharp rebar ends while maintaining grip on slippery steel surfaces. Avoid synthetic materials that melt from friction heat generated during cutting. Steel-toed work boots with slip-resistant soles prevent foot injuries from dropped rebar or cutters. Wear long sleeves made of natural fibers like cotton—synthetic fabrics can melt onto skin if contact occurs with hot metal. Never operate cutters while wearing loose clothing or jewelry that could catch in moving parts.

Workspace Safety Setup Checklist

Create a dedicated cutting zone with 6 feet of clear space in all directions—this prevents bystander injuries from flying debris. Secure rebar in a metalworking vise rated for at least 3 tons of force; woodworking clamps lack the necessary strength. Mark your cutting area with bright tape or cones to maintain safe distances. Position yourself with solid footing on level ground—never attempt cuts while standing on ladders or unstable surfaces. Keep a first aid kit stocked with metal-removal tweezers within immediate reach.

Precision Measuring and Marking Techniques

Professional-Grade Measuring Tools

Measure twice with a steel tape measure—cloth tapes stretch and create costly errors in rebar placement. Account for lap lengths required by your concrete specifications; most building codes require 40x bar diameter overlap. For curved rebar applications, create full-size templates from plywood before cutting. Double-check measurements against your blueprint dimensions before marking steel—correcting mistakes after cutting wastes valuable time.

Reliable Marking Methods for All Conditions

Soapstone markers outperform permanent markers on oily or rusty rebar surfaces common on construction sites. Make a single, crisp mark across the rebar diameter—multiple marks create confusion during cutting. Use a carpenter’s speed square to verify 90-degree cuts or create precise 45-degree angles for corners. Wipe away excess rust or oil with a rag before marking for maximum visibility. For repetitive cuts of identical lengths, create a cutting jig that eliminates measuring for each piece.

Secure Rebar Properly Before Cutting

Optimal Clamping Techniques

Position the cut line 2-3 inches from your clamp—this prevents blade damage while maintaining stability. Tighten clamps until the rebar won’t rotate under firm hand pressure. Use machinist’s vises with hardened jaws rather than standard woodworking clamps. For manual cutters, leave enough space behind the cut line for full jaw closure. Never hold rebar by hand during cutting—this common mistake causes severe hand injuries when the bar snaps.

Supporting Long Rebar Sections

Unsupported rebar can whip violently when cut, creating serious safety hazards. Support both sides of long sections with steel sawhorses—not wooden ones that can splinter. Position the free end to rest on the ground after cutting to prevent upward flipping. For pieces over 8 feet, have a helper stabilize the far end using leather gloves and proper hand placement away from the cut zone. Cut long sections in manageable 6-8 foot lengths before final precise cuts.

Execute Perfect Cuts Every Time

Manual Cutter Technique Masterclass

Place cutter jaws perpendicular to the rebar at your mark—angled positioning creates uneven cuts. Position your feet shoulder-width apart, applying pressure through your legs rather than just arm strength. Squeeze handles slowly until blades bite the steel, then increase pressure steadily. Listen for the distinctive “ping” sound indicating complete separation. Release handles slowly after cutting to control spring tension. Practice on scrap rebar to develop proper technique before cutting project pieces.

Electric Cutter Operation Protocol

Hold the cutter firmly with both hands, keeping all fingers clear of the blade path. Align your mark with the cutter’s guide fence before activating the blade. Squeeze the trigger smoothly—don’t force the cutter into the rebar. Maintain consistent pressure until the cut completes, then release the trigger immediately. Wait 3-5 seconds for the blade to stop completely before setting the tool down. Check blade guards are functioning properly before each use.

Maintain Your Cutter for Maximum Lifespan

Daily Maintenance Essentials

Wipe blades clean with a dry rag after each use to remove metal filings that accelerate wear. Apply light machine oil to cutting surfaces to prevent rust during storage. Inspect blades for nicks or chips before each project—damaged blades create dangerous kickback. Store cutters in a dry location away from moisture, preferably hanging vertically. Never leave cutters outside overnight—morning dew causes rapid corrosion on steel components.

Monthly Deep Maintenance Routine

Disassemble manual cutters monthly to clean pivot points and lubricate moving parts with lithium grease. Use compressed air to clear debris from electric cutter vents and cooling channels. Check hydraulic fluid levels and top off with manufacturer-specified oil. Inspect electrical cords for cuts or exposed wires—frayed cords cause dangerous shocks. Replace worn parts immediately rather than risking tool failure during operation.

Troubleshoot Common Cutting Issues

Fixing Uneven or Angled Cuts

Uneven cuts typically indicate improper rebar positioning or dull blades. Verify rebar sits perpendicular to cutter jaws before cutting. Replace blades showing visible wear—attempting to cut with dull blades increases force requirements and accident risk. For electric cutters, check guide fences remain straight and properly aligned. Practice cutting technique on scrap pieces before working on project materials.

Solving Cutter Jamming Problems

Jamming usually occurs when attempting to cut rebar beyond your tool’s capacity. Verify rebar size against your cutter’s specifications—oversized rebar damages tools. Check for blade chips or excessive wear that prevents clean cutting. On manual cutters, adjust pivot bolt tension if blades don’t close completely. Electric units may require professional motor servicing if they consistently stall during cutting.

Store Equipment for Longevity

Proper Storage Techniques

Store manual cutters with jaws closed and safety latch engaged to protect blade edges. Hang electric cutters by their handles—not by cords which damages internal wiring. Keep hydraulic units upright to prevent fluid leaks that damage seals. Use wall-mounted racks to organize tools and prevent damage from being stored on the ground. Apply rust preventative spray before long-term storage, especially in humid climates.

Environmental Protection Strategies

Moisture is the primary enemy of cutting tools—store in climate-controlled areas when possible. Place silica gel packets in storage containers to control humidity. Cover tools with breathable cotton cloth rather than plastic which traps moisture. Wipe down all metal surfaces with light oil before storage to prevent corrosion. Check stored tools monthly for signs of rust or damage during extended storage periods.

Mastering how to use a rebar cutter safely and effectively transforms a potentially dangerous task into a precise construction process. Start with smaller rebar sizes to build confidence, then progress to thicker materials as your technique improves. Remember that sharp blades, proper positioning, and consistent pressure matter far more than brute force. Keep your safety gear on for every cut, measure twice before marking, and maintain your tools regularly—these simple habits prevent most common cutting problems and ensure professional-quality results on every concrete project.