Nothing ruins a plumbing project faster than a crooked cut or crushed tubing. Whether you’re installing a new ice maker line or replacing copper pipes under the sink, mastering how to use a tube cutter is essential for leak-free connections. This guide walks you through every step—from choosing the right cutter to achieving professional-quality cuts that slide perfectly into fittings.

You’ll learn the exact techniques professionals use to cut copper, plastic, and steel tubing without deformation, plus troubleshooting tips for when things go sideways. By the end, you’ll confidently tackle any tubing project with clean, square cuts every time. Properly learning how to use a tube cutter separates DIY disasters from installations that last decades.

Choose Right Tube Cutter Type for Your Project

Standard cutters handle 1/8″ to 1-1/8″ tubing for most household plumbing. The cutting wheel scores metal as you rotate the tool, creating clean cuts in copper and brass. These workhorses tackle everything from refrigerator water lines to HVAC repairs without breaking the bank.

Mini cutters solve tight-space challenges where standard tools won’t reach. Their compact design handles 1/8″ to 5/8″ tubing—perfect for under-sink work or automotive repairs. Thumb-wheel adjustment allows one-handed operation in cramped quarters, making them invaluable for hard-to-access areas.

Heavy-duty models accommodate 1/4″ to 2″ tubing with reinforced frames. These power through steel pipe and thick-wall materials that would destroy standard cutters. Expect industrial-grade construction and larger cutting wheels designed specifically for demanding jobs.

Ratcheting cutters reduce hand fatigue during multiple cuts. The ratchet mechanism provides mechanical advantage, making 20+ cuts feel effortless. Size ranges vary but typically cover 1/4″ to 1-5/8″ tubing—ideal for professionals doing volume work.

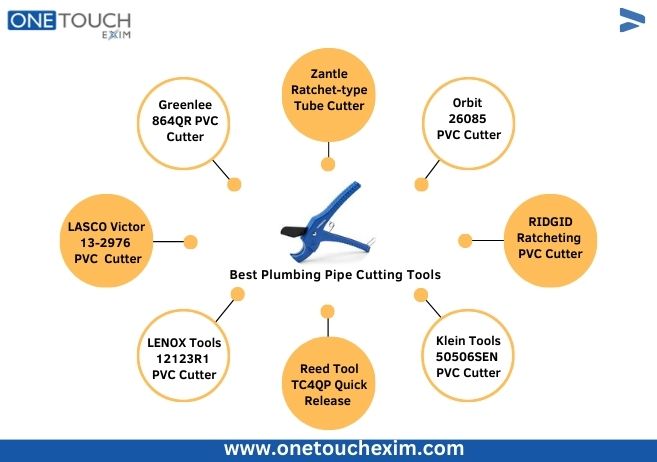

Plastic pipe cutters use sharp blades instead of wheels. Designed specifically for PVC, CPVC, and PEX, these prevent cracking that metal wheels can cause. The blade slices cleanly through plastic without deformation, ensuring watertight connections.

Essential Pre-Cut Preparation Steps You Can’t Skip

Inspect tubing thoroughly before cutting. Check for kinks, dents, or surface defects that compromise cut quality. Run your finger along the tubing length—any irregularities here will magnify in your final cut. Clean the exterior with appropriate solvent to remove oxidation, especially on aluminum tubing.

Mark cutting location precisely. Use a permanent marker or scribe to create a clear, thin line. Wrap masking tape around tubing first for darker marks on shiny copper. Double-check measurements—measure twice, cut once isn’t just a saying. A single millimeter off can mean disassembling an entire section.

Secure your workspace properly. Position tubing in a vise or clamp so the cut end falls freely without bending. Ensure adequate lighting to see the cutting wheel track clearly. Keep a deburring tool within arm’s reach—you’ll need it immediately after cutting. Unsecured tubing causes crooked cuts and potential injury.

Check cutter condition before starting. Inspect the cutting wheel for chips, flat spots, or excessive wear. A damaged wheel creates ragged cuts and requires replacement. Test the adjustment mechanism—turning should feel smooth, not gritty or binding. Lubricate pivot points if needed to ensure smooth operation.

Master the Cutting Process for Perfect Results

Initial Setup Steps for Square Cuts

Open the cutter completely by turning the adjustment knob counterclockwise until the cutting wheel and guide rollers clear your tubing diameter. Position the cutter exactly perpendicular to the tubing at your marked line—this angle determines squareness. Many professionals use a square against the tubing to verify 90-degree alignment before starting.

Close the cutter slowly until the wheel makes the lightest contact with the tubing surface. Verify the cutting track aligns perfectly with your mark. Misalignment now creates angled cuts that won’t seal properly. If you’re unsure, make a light test rotation to confirm alignment before applying pressure.

Execute Perfect Cuts Without Crushing Tubing

Apply gentle pressure and rotate the cutter one complete revolution to create an initial score line. This shallow groove guides subsequent passes and prevents wheel wandering. After the first revolution, tighten the adjustment knob only 1/8 turn clockwise—less for softer materials like copper.

Continue rotating with steady, consistent pressure. Think smooth, not rushed—jerky movements create uneven cuts. After 1-2 full revolutions, tighten another 1/16 to 1/8 turn. This gradual approach prevents tubing deformation while maintaining cutting efficiency. Pro tip: Listen for the sound of metal cutting metal—changes in pitch indicate issues.

Watch for the final separation. You’ll feel resistance decrease as the cut completes. Don’t force it—let the cutter do the work. Forcing causes oval cuts that leak at fittings. The final separation typically happens with minimal pressure as the tubing wall thins.

Material-Specific Cutting Techniques for Best Results

Copper tubing requires minimal pressure. The soft metal deforms easily under excessive force. Apply cutting oil to lubricate the wheel and extend tool life. Support tubing near the cut to prevent bending during final separation—this is especially crucial for thin-wall copper.

Aluminum tubing needs even less pressure than copper. Clean surfaces thoroughly—aluminum oxide is abrasive and dulls cutting wheels quickly. Expect more revolutions due to material softness, but resist increasing pressure. Aluminum’s malleability means it cuts easily but deforms readily.

Steel tubing demands patience. Use heavy-duty cutters rated for steel and apply cutting oil liberally. Expect 3-5 times more revolutions than copper. Apply significant pressure but avoid over-tightening, which can deform the tubing. Check your cutter’s specifications—some aren’t designed for steel at all.

Plastic tubing cracks under excessive pressure. Use plastic-specific cutters or sharp blade cutters. Score lightly first, then increase pressure gradually. Cold plastic becomes brittle—warm slightly if working in cool conditions. PVC and CPVC cut differently than flexible PEX, so adjust technique accordingly.

Post-Cut Finishing Steps Every Professional Performs

Remove burrs immediately after cutting. Internal burrs restrict flow and damage O-rings in push-fit fittings. Use an internal deburring tool or reamer—twist clockwise while applying gentle pressure. External burrs prevent proper fitting seating and create leak paths.

Check cut quality systematically. Hold a square against the cut face—maximum deviation should be 2 degrees from perpendicular. Measure tubing diameter with calipers before and after cutting. Diameter reduction over 0.002″ indicates excessive pressure during cutting.

Inspect the cut surface under good lighting. Look for smooth, consistent surface finish without significant gouges or chatter marks. Any roughness indicates a dull wheel or excessive pressure during cutting. Run your finger along the edge—if it catches, you need more deburring.

Solve Common Cutting Problems Before They Ruin Your Project

Fix Uneven Cuts Fast Without Starting Over

Angled cuts result from improper cutter positioning. The cutter must be perfectly perpendicular before starting. If your cut drifts, stop immediately and re-position. Continuing creates worsening angles that won’t seal. Quick fix: Use a square to verify alignment before the first revolution.

Prevention technique: Draw a perpendicular reference line around the tubing to guide positioning. This visual aid ensures your cutter stays aligned throughout the cutting process. Many experienced plumbers swear by this simple but effective method.

Prevent Tubing Deformation That Causes Leaks

Oval cuts occur when pressure increases too quickly. The tubing wall collapses inward, creating fitting problems. Reduce tightening increments and allow more revolutions between adjustments. For copper, try 1/16 turn increments instead of 1/8.

Solution: Start with minimal pressure—increase gradually. If tubing deforms, cut 1/2″ beyond the mark and re-cut the damaged section. This saves time compared to replacing the entire tube. Soft materials like aluminum require extra caution.

Recognize Dull Cutting Wheels Before They Wreck Your Job

Warning signs: Requires excessive force, produces ragged cuts, or the wheel slips without cutting. Dull wheels create poor surface finish and may score tubing without cutting through. You’ll notice increased resistance and inconsistent cutting depth.

Test sharpness: Try cutting a scrap piece. Sharp wheels create clean scores immediately with minimal pressure. Replace wheels showing chips, flat spots, or requiring unusual force. Most quality cutters have replaceable wheels—don’t try to sharpen them.

Maintain Your Tube Cutter for Long-Lasting Performance

Clean after every use to prevent corrosion. Wipe metal filings and plastic debris from cutting wheels and guide rollers. Use compressed air to clear hard-to-reach areas—buildup affects alignment and cutting quality. A quick wipe takes seconds but extends tool life significantly.

Lubricate moving parts regularly. Apply light machine oil to adjustment screw threads every 10-15 uses. Lubricate the cutting wheel pivot point to maintain smooth operation. Avoid over-lubrication that attracts grit and compromises performance.

Store properly to extend tool life. Keep in a dry location to prevent rust. Store with adjustment mechanism partially closed to maintain spring tension. Protect the cutting wheel edge from damage during storage—many cutters come with protective caps for this purpose.

Safety Essentials When Learning How to Use a Tube Cutter

Wear safety glasses—metal and plastic fragments fly unpredictably during cutting. Cut-resistant gloves protect hands from sharp burrs on freshly cut tubing. Long sleeves prevent arm injuries when handling cut ends. Safety isn’t optional—it’s part of professional work.

Never exceed cutter capacity. Check ratings printed on the tool frame. Forcing oversized tubing damages the cutter and creates dangerous kickback. Support tubing adequately to prevent unexpected movement during cutting. If it feels wrong, it probably is.

Keep first aid supplies accessible. Minor cuts happen despite precautions. Know your facility’s eye wash station location for debris removal. Report significant injuries immediately—don’t tough it out. Your health matters more than finishing the job.

Mastering how to use a tube cutter transforms frustrating plumbing projects into satisfying successes. Remember: sharp tools, gradual pressure, proper support. These three principles guide every successful cut. Practice on scrap tubing first, then tackle your actual project with confidence.

Your future self will thank you when those connections hold tight and your work looks factory-perfect. Clean, square cuts separate amateur work from professional installations—they’re the foundation of leak-free plumbing that lasts for decades. With these techniques in your toolbox, you’re ready to handle any tubing project that comes your way.