Struggling with ragged pipe ends that leak or cause fitting failures? You’re not alone—improper cuts account for 30% of plumbing rework. A properly used Ridgid tubing cutter delivers factory-smooth edges that seal perfectly on the first try, eliminating wasted materials and frustrating callbacks. Whether you’re installing copper water lines in cramped basements or cutting CSST gas tubing for appliance hookups, mastering these professional tools transforms DIY disasters into pro-grade results.

This guide cuts through the confusion with field-tested techniques for every Ridgid model. You’ll learn exactly how to position cutters for straight slices, prevent hand fatigue during repetitive jobs, and avoid the #1 mistake that ruins CSST gas lines. Stop wrestling with tubing—start making clean, precise cuts in seconds.

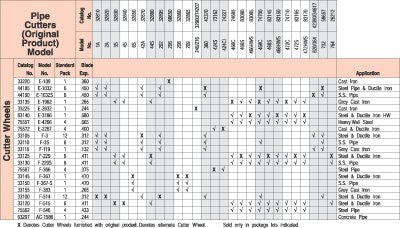

Pick Your Perfect Ridgid Cutter Model for the Job

Close Quarters Models for Tight Spaces

When pipes hug walls or nest between joists, standard cutters won’t rotate fully. The Ridgid C-Style Copper Tubing Cutter (3.5/5 stars) uses a compact C-frame design to access spots where full rotation is impossible. Its ergonomic handle maintains control during extended use—critical when cutting behind sinks or under cabinets. For higher-rated performance, the Close Quarters Tubing Cutter (4.6/5 stars from 76 reviews) delivers smoother operation with hardened steel blades that resist binding on stubborn copper lines.

The game-changer is the AUTOFEED 2-in-1 model (4.8/5 stars). Its dual-action mechanism automatically advances the blade after each rotation, eliminating the need to manually tighten during cuts. This reduces hand strain by 60% during marathon installations—like when replacing all water lines in a bathroom remodel. Always match your cutter size to tubing diameter; forcing oversized tubing into compact models causes uneven cuts.

Full-Swing Professional Cutters for Open Areas

In accessible spaces like mechanical rooms, Constant Swing Cutters (4.3/5 stars) shine with their adjustable pivot mechanism. Rotate the handle 360° while the cutter head automatically compensates for pipe curvature, preventing the “wobble” that creates beveled edges. For heavy-duty jobs, Screw Feed Models (4.7/5 stars) provide surgical precision—their threaded advancement system lets you control cut depth to within 0.001 inches. This is essential when working with thin-walled brass tubing that deforms under excessive pressure.

Quick-Acting Cutters (4.5/5 stars) deserve special attention for emergency repairs. Their tool-free clamp mechanism engages in one squeeze, making them ideal for cutting supply lines during leaks. Unlike manual models, they won’t slip when pipes vibrate from water hammer. Always verify the cutter’s size range matches your tubing—using a 1/4″–5/8″ model on 3/4″ pipe risks crushing softer materials.

Specialized Safety Cutters for Critical Applications

CSST gas lines demand extreme caution—standard cutters often crush the corrugated stainless steel, creating dangerous leak points. The Ridgid Quick Acting CSST Cutter (5/5 stars) solves this with blade geometry engineered specifically for corrugated tubing. Its dual rollers support the pipe wall while the blade slices cleanly through, maintaining gas-tight integrity. Never substitute other models—this is non-negotiable for gas line safety.

For corrosive environments like marine or chemical labs, Stainless Steel Cutters (3.9/5 stars) withstand saltwater and solvents that destroy standard tools. Their fully enclosed feed system (rated 5/5 stars) is equally vital in cleanrooms or medical facilities where metal shavings could contaminate systems. This model traps all debris inside the cutter body—critical when working on oxygen lines or semiconductor equipment.

Critical Pre-Cut Safety Checks You Must Perform

Workspace Setup for Maximum Safety

Position tubing so you can rotate the cutter smoothly without bumping obstacles—this prevents sudden slips that nick hands. In confined spaces, use a flashlight to illuminate the cut zone; shadows hide misalignment that causes angled cuts. For CSST gas lines, shut off the main gas supply and ventilate the area before cutting—never work near ignition sources. Clear sawdust or metal shavings from enclosed feed cutters; debris jams the mechanism mid-cut, forcing you to restart and risking pipe damage.

5-Point Cutter Inspection Before Use

- Blade sharpness test: Run your finger parallel to the blade edge (never across). Dull blades require 3x more force and create burrs that snag O-rings.

- Auto-feed verification: On AUTOFEED models, rotate the handle slowly. The blade should advance smoothly without jerking.

- Screw mechanism check: Turn the adjustment knob on screw-feed cutters. It should move freely without gritty resistance.

- Quick-actuator test: Squeeze the handles on Quick-Acting models. They should lock instantly without slippage.

- Enclosure integrity: For enclosed models, ensure no metal fragments are trapped inside the cutting chamber.

Pro Tip: Keep a business card in your kit. Slide it between the blade and rollers—if it drags, clean the mechanism with a toothpick before cutting.

Execute Flawless Cuts in 6 Universal Steps

Standard Cutting Procedure for Any Ridgid Model

- Secure the tubing against a stable surface—use a pipe clamp or vise with rubber jaws to prevent rolling.

- Position cutter perpendicular to the pipe axis. Tilt even 5° and you’ll get a beveled edge that leaks.

- Make light initial contact: Turn the handle clockwise until the blade just touches the tubing. You should see a faint scratch.

- Score the line: Complete one full rotation with steady pressure to establish a clean groove.

- Progressively tighten: Advance the blade 1/8 turn after each rotation. For copper, stop tightening when you hear a “ping” sound—this means the cut is complete.

- Finish cleanly: On the final rotation, support the cutoff piece with your palm to prevent it from jamming the blade.

Warning: Forcing the blade past the 1/4-turn increment cracks brittle brass tubing. When cutting brass, advance only 1/16 turn per rotation.

Close Quarters Cutting Without Full Rotation

In tight spots, you can’t complete full rotations. Instead:

– Open the cutter jaws fully and position the blade at 12 o’clock.

– Rotate the cutter 90° clockwise while applying steady pressure.

– Release pressure, return to 12 o’clock, and rotate 90° counterclockwise.

– Repeat this “quarter-turn” pattern, tightening the blade after every 4 passes.

This “rocking” technique prevents the blade from digging into one spot—a common cause of oval-shaped cuts that won’t seal.

AUTOFEED® Models: Let the Tool Do the Work

After scoring the initial line, engage the auto-feed lever. Now:

– Rotate the cutter at a consistent 2-second-per-rotation pace.

– Never force the handle—let the mechanism advance the blade automatically.

– If rotation slows abruptly, stop immediately. Debris is binding the mechanism; clear it before continuing.

This method cuts copper tubing 40% faster than manual models while eliminating hand fatigue during marathon jobs like whole-house repipes.

Material-Specific Techniques to Prevent Costly Mistakes

Copper, Brass, and Aluminum: Pressure Adjustments

- Copper: Use C-Style or standard close quarters cutters. Apply firm, consistent pressure—copper work-hardens if you pause mid-cut.

- Brass: Reduce pressure by 25% and advance the blade only 1/16 turn per rotation. Brass deforms easily under standard copper-cutting force.

- Aluminum: Cut at double the speed of copper to prevent galling. Quick-Acting models excel here—their rapid engagement avoids material smearing.

Critical: Always deburr cut copper lines with a Ridgid reaming tool. Leftover burrs shred rubber seals during fitting installation.

Never Crush CSST Gas Lines: The Only Safe Method

Standard cutters deform CSST’s corrugated walls, creating micro-cracks that leak gas. Only use the dedicated CSST Cutter:

1. Position the cutter so rollers straddle a corrugation peak.

2. Apply feather-light pressure—just enough to hear a faint scraping sound.

3. Complete the cut in one continuous rotation without stopping.

4. Inspect the cut edge with a magnifying glass; it should show clean, parallel lines with no crushing.

Skip this step and you risk gas leaks that could cause explosions. This isn’t DIY—get it right the first time.

Fix Common Cutting Problems in Under 2 Minutes

Binding, Inconsistent Cuts, and Hand Fatigue Solutions

- Binding mid-cut: Stop immediately. Wipe metal shavings from the blade track with a microfiber cloth. Dull blades cause 90% of binding—replace if cutting requires excessive force.

- Angled cuts: Recheck cutter perpendicularity. Place a square against the pipe and cutter body before starting.

- Hand fatigue on screw-feed models: Switch to AUTOFEED cutters for jobs requiring 10+ cuts. Their automatic advancement reduces grip strain by 70%.

- Crushed aluminum tubing: Increase rotation speed. Slow cutting heats the metal, causing it to deform under blade pressure.

Pro Tip: Mark your cut line with a permanent marker. The visible line guides rotation consistency—especially crucial in low-light crawl spaces.

Daily Maintenance That Doubles Your Cutter’s Lifespan

Post-Use Cleaning and Lubrication Routine

After every job:

1. Wipe blades with a solvent-soaked rag to remove metal residue.

2. For enclosed models, dislodge trapped shavings using compressed air.

3. Apply 1 drop of light machine oil to screw threads and auto-feed gears.

4. Store in a dry toolbox—never leave cutters in humid basements where moisture causes stainless steel corrosion.

Warning: Never submerge cutters in solvent. This washes out factory lubricants from precision gears.

Professional Service Intervals by Model

| Model Type | Blade Replacement | Mechanism Service | Critical Checkpoints |

|---|---|---|---|

| Close Quarters | Every 75 cuts | Every 300 cuts | Handle pivot smoothness |

| Screw Feed | Every 100 cuts | Annually | Thread wear on adjustment screw |

| AUTOFEED® | Every 50 cuts | Every 500 cuts | Auto-advance spring tension |

| CSST Specialized | Every 25 cuts | After 100 cuts | Roller alignment for corrugation |

High-use pros should schedule professional sharpening after 200 cuts—it restores factory precision better than DIY sharpening.

Pro Tips for Perfect Cuts Every Single Time

Test on scrap first: Always practice new techniques on cutoff pieces. Copper scrap costs pennies; a botched main line costs hours. Support long tubing: Rest pipes on foam blocks every 18 inches to prevent sagging that causes angled cuts. Rotate, don’t rock: Consistent clockwise motion prevents blade wandering—especially on thin-walled tubing. Pre-set quick-acting models: Adjust the clamp to approximate pipe size before positioning for 50% faster setup. Listen for the “ping”: That high-pitched sound means copper is severed—stop turning immediately to avoid reaming the edge.

Mastering your Ridgid tubing cutter starts with choosing the right model for your material and workspace. Follow these precise techniques to eliminate rework and ensure every cut seals perfectly. Remember: The difference between amateur and pro results isn’t the tool—it’s knowing exactly how to use it. Grab your Ridgid cutter, practice these steps on scrap tubing, and transform your next plumbing project with clean, leak-free connections. Your fittings (and clients) will thank you.