Nothing halts production faster than grabbing the wrong Miller plasma cutter tip when you’re ready to cut. You’ve experienced it—ordering the wrong consumable, wasting precious hours, and watching your project timeline evaporate. Whether you’re slicing through steel with a Spectrum 375 X-TREME on a construction site or crafting precision parts with an ICE-100T in the shop, the right tip makes all the difference in cut quality, consumable lifespan, and your bottom line. This guide cuts through the confusion to deliver exactly what you need to know about Miller plasma cutter tips—no fluff, just actionable information that gets you back to cutting.

Stop guessing which tip belongs in your torch. You’ll discover the precise amperage match for your material thickness, when extended reach is actually necessary (not just convenient), and how to avoid the top three mistakes that cost fabricators hundreds in wasted consumables each year. By the end of this guide, you’ll confidently select the correct Miller plasma cutter tip every time, maximizing cut quality while minimizing downtime and expense.

How Amperage Determines Your Miller Plasma Cutter Tip Selection

Your cutting amperage isn’t just a number—it’s the foundation of proper tip selection. Miller engineers each tip’s orifice size specifically for optimal arc characteristics within designated amperage ranges. Choosing outside this range creates immediate problems: too small an orifice for your amperage and you’ll blow out consumables; too large and you’ll suffer poor arc stability with ragged cuts.

12 Amp Tips: Precision Cutting for Thin Materials

When working with sheet metal under 1/8″ thick, the ICE-12C’s 12 Amp tips deliver surgical precision impossible with larger tips. These tips create an exceptionally focused arc perfect for detailed artwork, HVAC ductwork, and delicate fabrication where edge quality matters more than speed. The smaller orifice maintains stable arc characteristics at low amperages that would cause larger tips to sputter and fail. Fabricators specializing in decorative metalwork or thin-gauge applications report up to 30% longer consumable life when using these specialized tips instead of downgrading from higher-amperage models.

30 Amp Tips: The General Fabrication Workhorse

The 30 Amp tips represent the sweet spot for most small to mid-sized shops running XT30 or XT40 torches. These tips cleanly cut through 1/4″ mild steel while maintaining respectable consumable life—typically 1-2 hours of actual cutting time depending on material condition. When cutting thicker materials approaching 3/8″, you’ll notice increased dross and slower cut speeds, signaling it’s time to switch to a 40 Amp tip. Many Spectrum 375 X-TREME operators make the mistake of using 30 Amp tips for all jobs, not realizing their machine can handle 40 Amp tips for heavier cutting when needed.

40 Amp Tips: Maximum Compatibility for Medium Thickness Cutting

With compatibility spanning XT40, ICE-40, and multiple ICE-60T/TM/80T/TM/100T/TM models, 40 Amp tips offer the broadest utility across Miller’s product line. These handle 3/8″ material with authority while still performing adequately on thinner stock down to 1/8″. The wider orifice maintains arc stability through painted or slightly rusty surfaces better than smaller tips, making them ideal for field work where perfect material prep isn’t possible. Shops maintaining multiple Miller machines find stocking 40 Amp tips covers approximately 60% of their cutting needs, reducing inventory complexity without sacrificing performance.

60 Amp Tips: Power Through Thick Material

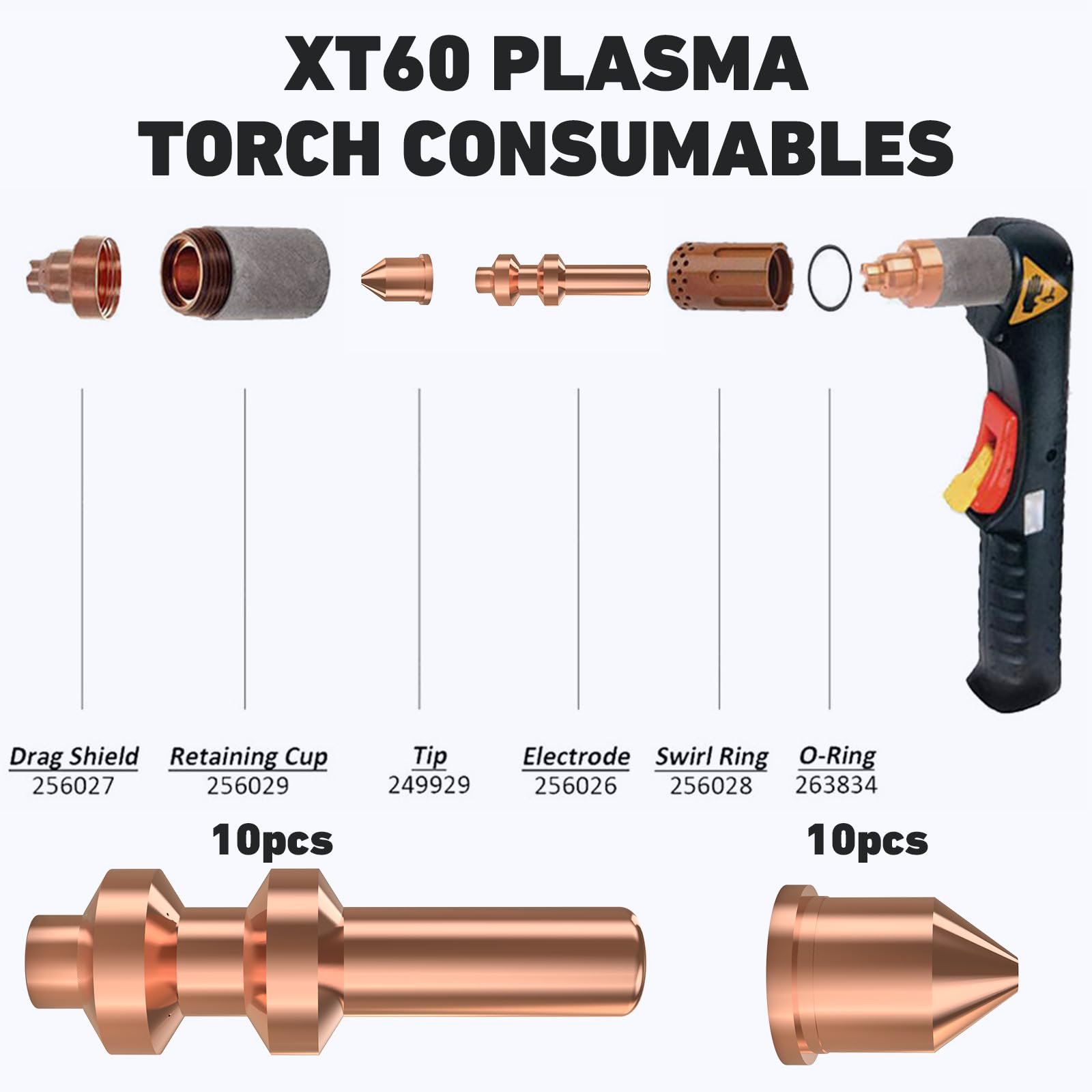

When facing 1/2″ steel or thicker, 60 Amp tips provide the necessary power with XT60 and compatible ICE-series torches. These tips sacrifice some precision on thin materials but deliver impressive speed on heavy plate—cutting 1/2″ steel at nearly twice the speed of 40 Amp tips. The tradeoff comes in consumable cost; these tips typically cost 25-40% more than lower-amperage models and wear faster when used below their optimal thickness range. Smart operators reserve these for heavy cutting days, switching back to 40 Amp tips for lighter work to maximize overall consumable value.

Extended Reach Tips: Solving Real-World Access Problems

Extended cutting tips aren’t just longer—they’re engineered solutions for specific access challenges that standard tips can’t overcome. These specialized Miller plasma cutter tips add crucial inches of reach without compromising arc stability, but they come with important considerations many users overlook.

When Extended Reach Actually Saves Time (And When It Doesn’t)

Don’t fall for the misconception that extended tips are universally better. They create more heat buildup in the torch head, accelerating wear on electrodes and shields. Use them only when you genuinely can’t position a standard tip within proper standoff distance (1/8″ to 3/16″). For example, cutting inside structural steel channels or modifying automotive frames often requires extended reach, while flat plate work rarely does. Shops that reserve extended tips for specific applications report 20-30% longer overall consumable life compared to those using them as general replacements.

Model-Specific Extended Tip Compatibility

ICE-55 series torches exclusively use extended cutting tips—no standard options exist. ICE-40, 80T/CX, and 100T models offer flexibility, accepting both standard and extended configurations. This versatility allows operators to switch between modes as job requirements change without torch modifications. Always verify your specific ICE model prefix (T, TM, CX, CXM) as compatibility varies within the same amperage rating—ICE-80T and ICE-80CX may require different extended tips despite similar naming.

Gouging Tips: Transform Your Plasma Cutter Into a Metal Removal Tool

Gouging tips fundamentally change your plasma cutter’s function from clean separation to aggressive metal removal. The key difference lies in the shield design—gouging tips use a deflector that spreads the arc rather than focusing it, creating a wider, hotter stream ideal for removing welds or preparing joints.

XT Series Gouging Configuration

The 30/40A Shield Deflector works with XT30/40 torches standard on Spectrum 375 and 625 X-TREME units. This configuration delivers controlled metal removal at speeds up to 10 inches per minute on 1/2″ steel. For best results, maintain a 30-45 degree angle to the workpiece and move steadily—hesitation causes excessive melting while rushing creates shallow, ineffective gouges. Many operators don’t realize they can switch back to cutting tips without torch modifications, making these machines true dual-purpose tools.

ICE Series Heavy-Duty Gouging

For industrial applications, ICE-60T/TM and 100T gouging tips handle deeper, wider removal tasks. These tips create U-grooves up to 3/8″ wide and 1/4″ deep in a single pass, significantly faster than grinding. The wider deflector design requires slightly higher amperage (minimum 50A) for optimal performance—running these tips below specification creates inconsistent results and rapid wear.

Torch-Specific Compatibility You Can’t Afford to Ignore

Miller’s compatibility matrix contains critical nuances that determine whether a tip will function properly or cause immediate damage. The ICE-12C serves as the starkest example—its 12 Amp tips won’t fit any other torch, and attempting to force other tips into it damages both the consumable and torch head.

XT Series Compatibility Secrets

XT30 torches accept both 30 and 40 Amp tips, but most operators don’t realize 40 Amp tips in an XT30 require reduced amperage settings (max 35A) to prevent premature wear. XT40 torches technically fit 30 Amp tips, but this combination wastes the torch’s full capability—reserve 30 Amp tips for XT30-specific applications where lighter cutting justifies the reduced power.

ICE Series Compatibility Pitfalls

ICE-25/27 series require non-shielded tips—a critical distinction many miss when upgrading from older models. These tips lack the outer shield component, designed specifically for applications where shielding gas isn’t available or necessary. Using standard shielded tips in these torches creates dangerous gas leaks and inconsistent cutting performance.

Proven Maintenance Practices That Double Tip Life

Clean compressed air represents the single biggest factor in Miller plasma cutter tip longevity. Moisture in your air supply causes rapid oxidation inside the tip orifice, distorting the arc and creating uneven wear. Install an inline air dryer with a moisture indicator and drain your compressor tank daily—this simple practice can double consumable life, especially in humid environments.

Maintain precise standoff distance—1/8″ to 3/16″ for most applications. Too close and you’ll blow out the swirl ring; too far and cut quality suffers while heat builds in the tip. Use a standoff gauge specific to your torch model, checking it every 30 minutes during extended cutting sessions. Fabricators who monitor standoff distance report up to 40% longer tip life compared to those who don’t.

Prepare your material properly. A quick wire brush pass removes surface contaminants that force the arc to work harder, overheating the tip. Cutting through rust, paint, or oil can reduce consumable life by 50% or more. For critical applications, consider grinding a small starting point—this prevents the initial arc blast from damaging the tip as it penetrates the material.

Smart Inventory Management for Maximum Uptime

Stock 40 Amp tips as your primary inventory—they cover the widest range of applications across Miller’s product line. Add 30 Amp tips for precision work on thin materials and 60 Amp tips only if you regularly cut 3/8″ or thicker steel. Extended reach and gouging tips should represent no more than 20% of your total inventory, reserved for specific job requirements.

Rotate your stock using the “first in, first out” method. Plasma tips have a limited shelf life—oxidation can occur even in storage, especially in humid environments. Check your oldest tips monthly for discoloration or pitting, discarding any that show signs of deterioration before they damage your torch.

Selecting the right Miller plasma cutter tip transforms frustration into productivity. Match your amperage to material thickness first, then consider specialty configurations only when job requirements demand them. Maintain clean air, proper standoff, and material preparation to maximize consumable life, and stock strategically based on your actual cutting needs rather than theoretical possibilities. With this approach, you’ll spend less time troubleshooting consumables and more time cutting profitably—exactly what your business needs.