That frustrating moment when your plasma cutter starts sputtering and leaves jagged edges on your metal project? Nine times out of ten, mismatched or worn plasma cutter tips are to blame. Most beginners waste hundreds of dollars replacing the wrong consumables or struggling with poor cuts before discovering the simple compatibility rules that professionals rely on. This guide reveals exactly which plasma cutter tips work with your specific machine model, how to extend their lifespan by 300%, and where to find the best value kits that actually perform.

Your first investment shouldn’t be in expensive replacements but in understanding which consumables match your torch system. Whether you’re using a CUT-40, AG60, or YESWELDER CUT-55DS Pro, the right plasma cutter tips transform frustrating projects into clean, precise cuts that save both time and money. By the end of this guide, you’ll know exactly which consumables to order, how to spot quality issues before installation, and the daily checks that prevent 90% of cutting failures.

Fix Mismatched Plasma Cutter Tips Before Your Next Project

Installing incompatible consumables destroys cut quality instantly and risks permanent torch damage. Your machine’s performance depends entirely on using the exact consumable series designed for your torch model—no substitutions work reliably.

PT-31 Torch Systems: The Most Common Beginner Mistake

Compatible with: CUT-40, CUT-45, CUT-50, CT-312, MIG205 MP

– Best starter kit: 60PCS PT31 consumables ($12.99, 4.8/5 stars from 48 reviews)

– Critical detail: Extended nozzles handle 3/8″ material without damaging your torch

– Pro tip: Check for “PT-31” marking on your torch body—don’t trust generic “CUT-series” labels

AG-60/SG-55 Systems: Precision for Thicker Materials

Compatible with: AG60, WSD60, BTC500DP, STC750P

– Budget winner: AG60P 26-piece kit ($9.99) includes storage box

– Size specification matters: .040″ nozzles for sheet metal, .045″ for structural steel

– Warning: AG-60 and SG-55 consumables are cross-compatible—don’t pay premium prices for “exclusive” kits

IPT40 Systems: YESWELDER-Specific Precision

Compatible only with: CUT-55DS Pro, CUT-60DS PRO, CUT-65DS Plus

– No alternatives: YESWELDER 24-piece kit ($41.39) is the only option

– Value insight: These premium consumables last 3x longer than generic brands

– Critical check: Verify “IPT40” on your torch—CUT-55 models have two different torch systems

Build Your Consumable Arsenal Without Breaking the Bank

Running out of plasma cutter tips mid-project costs 5x more than smart stocking. Professionals keep specific kits ready based on their most common projects, avoiding expensive emergency orders and machine downtime.

Budget Starter Kit for Weekend Warriors

- AG60P 26-piece kit: $9.99 covers 20+ cuts on thin materials

- PT31 60-piece kit: $12.99 provides backup for common failures

- Total investment: $22.98 solves 80% of beginner consumable needs

- Pro tip: Store kits in original packaging to prevent contamination

Heavy-Duty Workshop Setup for Pros

- 100-piece SG-55 kit: $41.49 reduces reorder frequency for STC750P users

- 150-piece PT-31 extended kit: $29.90 handles thick materials without constant replacements

- Key advantage: Storage boxes included with bulk kits keep consumables organized

- Warning: Avoid kits without storage—loose consumables get damaged during transport

Spot Quality Issues in Cheap Kits

- Copper discoloration: Indicates poor manufacturing quality control

- Ceramic cracks: Cause inconsistent arc starts and ruined cuts

- Loose electrode fit: Damages torch threads within weeks of use

- Pro verification: Compare new electrodes to old ones—consistent weight indicates quality

Decode Plasma Cutter Tip Part Numbers in 60 Seconds

Stop guessing which consumable fits your torch—these visual identifiers prevent costly mistakes. Matching part numbers to your specific machine model takes just seconds when you know what to look for.

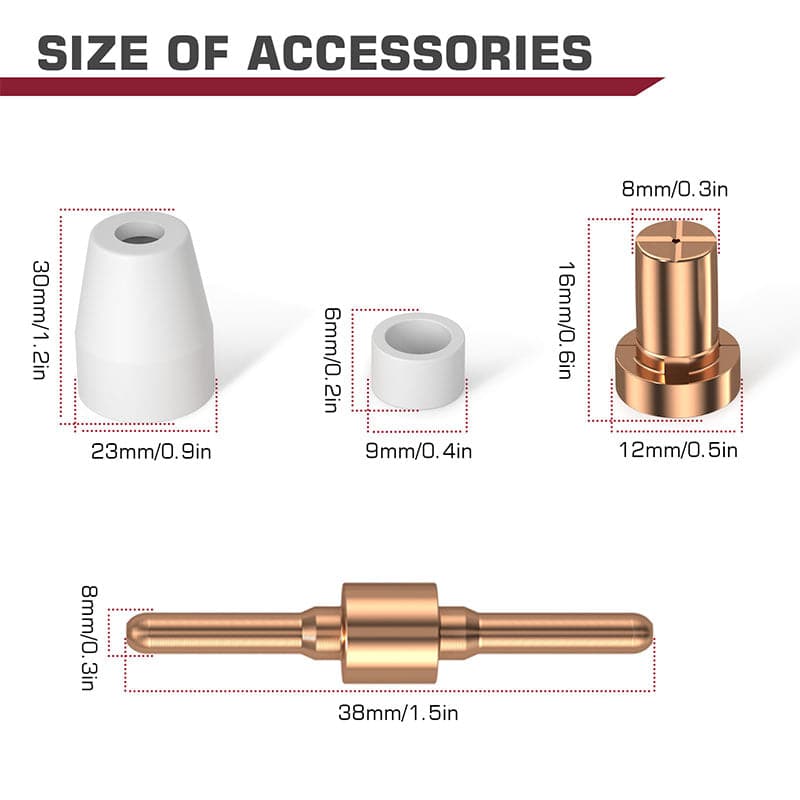

PT-31 Series Visual Identification

- Nozzle color coding: Black = standard reach, Silver = extended for thicker materials

- Electrode wear indicator: Sharp point = new, Rounded tip = replace immediately

- Shield cup types: Ceramic = high-heat applications, Metal = general purpose cutting

AG-60 Series Quick Reference

- Nozzle size marking: .040″ or .045″ stamped on rim for instant identification

- Ceramic cup thickness: Thicker cups handle 60+ amp settings without cracking

- Electrode length matching: Critical for proper gas flow—measure against old consumables

Organize Your Consumables for Instant Access

Use this drawer system for stress-free project starts:

– PT-31 Nozzles: Separate black (standard) and silver (extended)

– Electrodes: Group by torch series (PT-31, AG-60, IPT40)

– Shield cups: Categorize ceramic vs. metal types

– Pro tip: Label containers with compatible machine models (CUT-40, AG60, etc.)

Prevent 90% of Plasma Cutter Failures With Daily Checks

Most cutting problems stem from overlooked consumable issues—not machine faults. These field-tested plasma cutter tips eliminate common headaches before they ruin your project.

4-Step Pre-Cut Checklist

- Electrode inspection: Replace when pit depth exceeds 1mm (use calipers for accuracy)

- Nozzle orifice check: Reject any with oval wear or spatter buildup

- Gas flow verification: Listen for consistent hissing sound—gurgling indicates moisture

- Tightness test: Finger-tight plus 1/8 turn maximum to avoid thread damage

Consumable Lifespan Visual Guide

- New electrode: Bright copper color with sharp central point

- 50% life remaining: Slight rounding at tip but still cuts cleanly

- Replace immediately: Black oxidation, dull tip, or poor arc starts

Cut Quality Troubleshooting Flowchart

Problem: Jagged edges on cut line

– Cause: Worn nozzle orifice allowing unstable plasma stream

– Fix: Replace nozzle and inspect electrode condition

Problem: Arc won’t establish consistently

– Cause: Dirty electrode contact surface or insufficient air pressure

– Fix: Clean electrode with wire brush, verify 90+ PSI air supply

Problem: Excessive dross (molten metal residue)

– Cause: Wrong nozzle size for material thickness

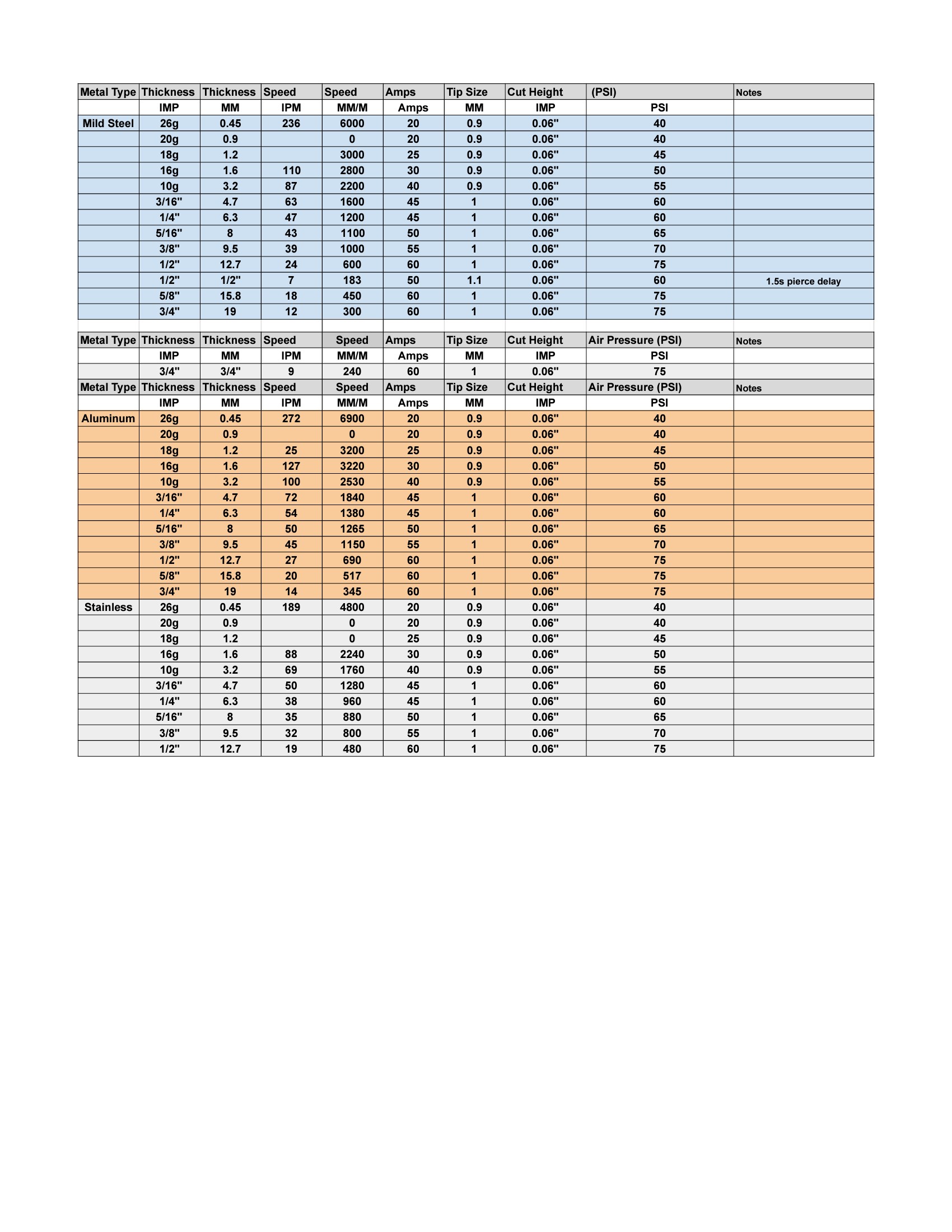

– Fix: Match nozzle size to thickness using the chart below

Match Plasma Cutter Tips to Material Thickness Perfectly

Using the wrong nozzle size creates costly rework—this quick-reference chart eliminates guesswork. Pair your material with the exact consumable specifications for clean, dross-free cuts.

| Material Thickness | Nozzle Size | Amperage Setting | Consumable Type |

|---|---|---|---|

| 16-14 gauge | .040″ | 20-25 amps | Standard PT-31 |

| 1/8″ | .045″ | 30-35 amps | AG-60 series |

| 1/4″ | Extended .045″ | 45-50 amps | PT-31 extended |

| 3/8″ | Extended .045″ | 60+ amps | AG-60 heavy-duty |

Extend Plasma Cutter Tip Life 300% With These Pro Moves

These field-tested techniques save hundreds annually in replacement costs while improving cut quality. Proper care transforms consumables from disposable parts into precision cutting instruments.

Air Quality Control That Matters

- Install water separator: Prevents moisture damage to electrodes

- Filter maintenance: Change compressor filters every 50 cutting hours

- Tank drainage: Empty air tank daily to prevent rust particles in air stream

Cutting Technique Refinements

- Standoff distance: Maintain 1/8″ for clean cuts, closer only for intricate work

- Travel speed: Watch for sparks exiting bottom of cut—adjust speed accordingly

- Piercing technique: Start 1/4″ above surface, lower after arc establishes

Storage Best Practices

- Original packaging: Keeps consumables clean until installation

- Dry environment: Prevents oxidation that ruins electrode conductivity

- Stock rotation: Use oldest consumables first to avoid shelf degradation

Upgrade Your Plasma Cutter Tips or Stock Up: The Profitability Decision

Knowing when to invest in better consumables saves money long-term. Track these indicators to determine whether upgrading your plasma cutter tips makes financial sense for your workflow.

Upgrade Indicators

- Weekly consumable orders: Your volume justifies better torch system

- Persistent cut quality issues: Consider IPT40 series for precision work

- Torch overheating: Step up to AG-60 series for heavy use applications

Smart Stock-Up Timing

- Before major projects: Order 3x normal usage to avoid workflow interruptions

- During seasonal sales: PT31 kits drop to $9.99 during Amazon promotions

- End of year: Tax deductions apply to consumable purchases for business owners

Order the Right Plasma Cutter Tips in 30 Seconds (Machine-Specific Guide)

Find your exact match instantly with this quick-reference system. No more confusing part numbers or compatibility questions—just the precise consumables your machine needs.

CUT-40/CUT-50 users: PT-31 series consumables, 60-piece kit minimum

CT-312 owners: PT-31 extended nozzles for 3/8″ capacity

AG60 machine users: AG-60P 40-piece kit balances cost and quantity

YESWELDER CUT-55DS: IPT40 series only—no substitutes work

STC750P operators: SG-55/AG-60 consumables, 100-piece bulk recommended

Your plasma cutter transforms from frustrating tool to profit center when you match the right plasma cutter tips to your specific torch system. Start with the budget-friendly 60-piece PT31 or 26-piece AG60P kit based on your machine model, then scale up as your projects demand. Remember the golden rule: quality consumables cost less long-term through fewer replacements and better cuts. Track your consumable usage for just one month, and you’ll discover exactly where to optimize your spending while dramatically improving your cutting results.