You’ve got aluminum sheet metal waiting to be cut and a plasma cutter gathering dust in your workshop. The question burning in your mind is simple: does a plasma cutter cut aluminum effectively? The answer is a resounding yes—modern plasma systems slice through aluminum with precision from thin sheets to plates over six inches thick. But achieving clean, professional results requires matching the right equipment with proper technique.

Plasma cutting aluminum has evolved dramatically since the 1980s when early systems produced inconsistent, messy cuts. Today’s technology delivers weld-ready edges on thick aluminum plates with minimal post-processing. Whether you’re fabricating boat parts, building aircraft components, or working on DIY projects, understanding how to optimize your plasma cutter for aluminum makes all the difference between frustrating failures and professional-quality results.

Why Aluminum Responds Perfectly to Plasma Cutting

Electrical Conductivity Creates Stable Arcs

Aluminum’s excellent electrical conductivity allows it to complete the circuit between your torch and workpiece effortlessly. Unlike non-conductive materials that resist plasma cutting, aluminum readily accepts the electrical arc, maintaining consistent cutting performance throughout your work. This conductivity ensures the plasma arc stays stable even when cutting complex shapes or intricate patterns.

Superheated Plasma Melts Aluminum Instantly

The plasma arc reaches temperatures exceeding 20,000°F—more than enough to melt aluminum’s 1,220°F melting point. This intense heat creates a concentrated cutting zone while the high-velocity gas stream blows molten material away from the kerf. The result? Clean, precise cuts with minimal heat-affected zone compared to oxy-fuel methods.

Selecting the Right Plasma System for Aluminum

Air Plasma Systems: Budget-Friendly Aluminum Cutting

Your entry-level Hypertherm Powermax system handles aluminum up to 1 inch thick using simple compressed air. These units deliver acceptable cut quality for most fabrication work without requiring special gas bottles or complex setup. For shops cutting mixed metals including occasional aluminum, air plasma provides the best balance of cost and performance.

Critical setup steps for air plasma aluminum cutting:

– Ensure clean, dry compressed air supply (moisture causes inconsistent arcs)

– Verify gas pressure at 80-90 PSI for optimal performance

– Check consumable condition—worn electrodes create erratic cutting

– Confirm solid workpiece grounding before starting

High-Definition Plasma: Professional Aluminum Results

Industrial systems like Hypertherm XPR series with dual-gas configurations produce weld-ready edges on aluminum without secondary preparation. Their vented water injection technology stabilizes the plasma arc while cooling the cut edge, delivering perpendicular, dross-free results even on thick plate. The VWI process also extends consumable life by up to 40% compared to standard plasma systems.

Extreme Thickness Cutting: Aluminum Plate Mastered

For serious aluminum cutting jobs, systems like the Hypertherm HPR800XD pierce through 3-inch thick aluminum from a standing start and sever 6-inch plates. These 800-amp industrial powerhouses use argon-hydrogen-nitrogen gas mixtures to maintain cut quality across the entire thickness range. Production shops working with heavy aluminum structures find these systems pay for themselves through reduced post-processing time.

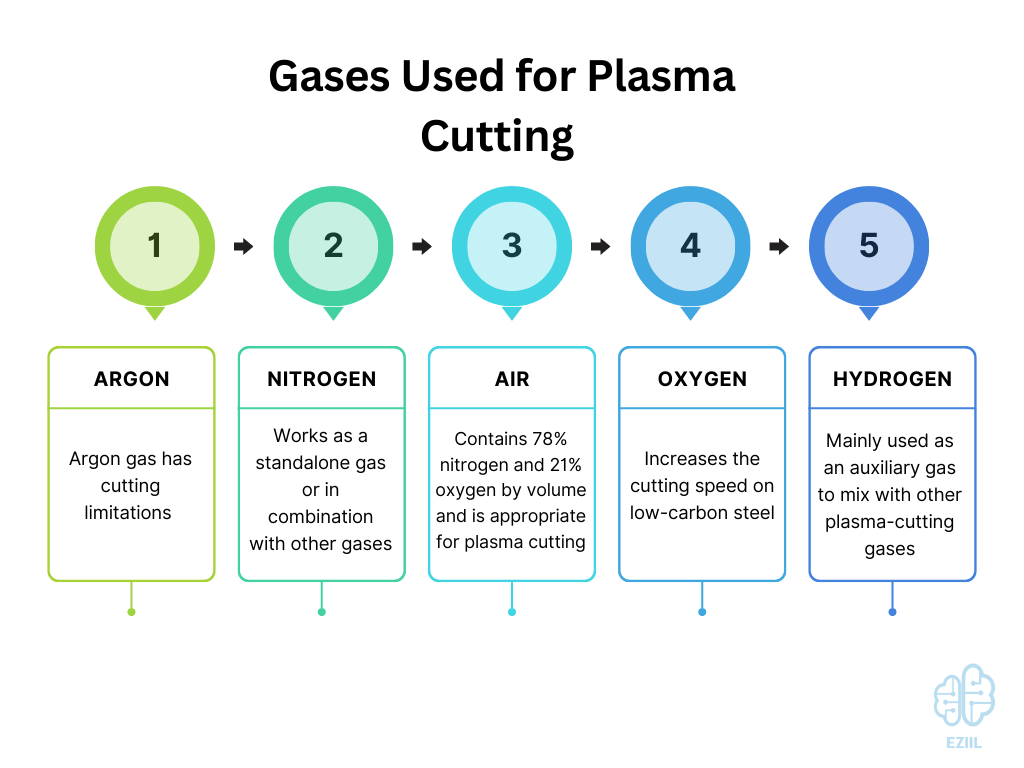

Gas Selection: The Secret to Perfect Aluminum Cuts

Air/Air Configuration: Simple but Limited

Compressed air remains the most cost-effective option for general aluminum cutting up to 25mm thick. While convenient and inexpensive, air-cut edges develop an aluminum oxide coating that requires removal before welding. This oxide layer appears as a dark, rough surface that compromises weld integrity if not addressed.

Nitrogen/CO₂: The Sweet Spot for Most Shops

Switching to nitrogen plasma gas with CO₂ shield gas dramatically improves edge quality on aluminum between 8-20mm thick. This combination delivers faster cutting speeds and cleaner edges than air systems while keeping operating costs reasonable. The nitrogen creates a more stable plasma arc while CO₂ shielding minimizes oxidation on the cut surface.

H35/N₂: Premium Results for Critical Applications

For aerospace-grade aluminum cuts, use H35 gas (35% hydrogen, 65% argon) as plasma gas with nitrogen shield. This premium combination produces the smoothest, most perpendicular edges possible—even on 4-inch thick aluminum. The hydrogen content increases plasma energy density while nitrogen shielding prevents oxidation. Though more expensive, this gas mix often eliminates secondary edge preparation for welding.

Aluminum Cutting Safety: Hidden Hazards to Avoid

Aluminum Dust Requires Special Handling

Aluminum dust mixed with steel dust creates a thermite reaction that can spontaneously ignite. Fabrication shops must maintain separate filtration systems for aluminum versus steel operations. Store aluminum cuttings away from ferrous materials entirely to prevent dangerous chemical reactions during storage.

Water Table Hydrogen Buildup Solution

Cutting aluminum on water tables produces hydrogen gas through the reaction between hot aluminum and water. Prevent dangerous accumulation with a simple DIY aeration system: drill 3mm holes every 150mm along PVC tubing connected to your shop airline. This continuous bubble stream safely disperses hydrogen before it reaches explosive concentrations.

Materials That Defy Plasma Cutting

Avoid cutting anodized aluminum—the heat damages the surface finish several inches from the cut line. Skip aluminum diamond plate entirely since the raised patterns interfere with arc height control, causing inconsistent cuts. Most critically, never cut aluminum-lithium alloys underwater due to extreme fire and explosion risks.

Achieving Professional Aluminum Cuts: Step-by-Step

Pre-Cut Setup Checklist

Start every aluminum cutting session with these critical steps:

1. Verify your gas selection matches aluminum thickness requirements

2. Check consumable condition—replace any worn nozzles or electrodes

3. Ensure proper workpiece grounding with a clean connection point

4. Set appropriate amperage based on material thickness

5. Confirm correct gas pressures using manufacturer specifications

During the Cut: What to Monitor

Watch these indicators while cutting aluminum:

– Travel speed: Too fast causes incomplete penetration; too slow creates excessive dross

– Arc voltage: Critical for automatic height control systems

– Dross formation: Indicates gas flow or speed issues

– Edge perpendicularity: Shows proper gas selection and amperage

Post-Cut Processing Guide

Your post-cut steps depend on gas selection:

– Air-cut edges: Remove oxide layer with stainless steel wire brush before welding

– Nitrogen-cut edges: Light cleaning usually sufficient for welding

– H35-cut edges: Often weld-ready with minimal preparation

– Thick plate: Light grinding may improve aesthetics for visible applications

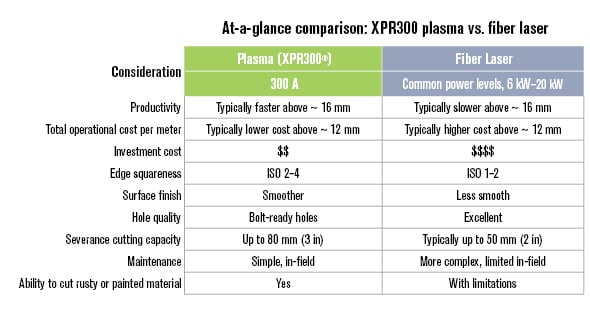

Plasma vs. Laser: Choosing the Right Aluminum Cutter

When Plasma Dominates Aluminum Cutting

Plasma systems outperform lasers on aluminum thicker than 20mm while costing significantly less. Equipment costs run 30-50% lower than comparable laser systems, with operating expenses favoring plasma for high-volume production. Setup complexity remains minimal—you can be cutting aluminum within minutes of system startup, making plasma ideal for job shops handling mixed materials.

Laser’s Niche in Aluminum Fabrication

Laser cutting excels on aluminum under 20mm thickness, delivering superior precision for intricate aerospace components requiring ±0.1mm tolerances. However, lasers struggle with reflective materials and become exponentially more expensive as thickness increases. For most general fabrication work involving aluminum, plasma provides better value and versatility.

Real-World Aluminum Cutting Performance

Quality Benchmarks to Expect

A properly tuned plasma system delivers dross-free aluminum cuts with perpendicular edges and smooth kerf profiles. Modern systems minimize the heat-affected zone compared to oxy-fuel cutting, preserving aluminum’s mechanical properties. Your cut surface should appear clean and consistent across the entire thickness when using appropriate gas combinations.

Productivity Metrics by Thickness

Cutting speed varies dramatically with aluminum thickness:

– 6mm aluminum: 200 inches per minute with 200-amp system

– 12mm aluminum: 120 inches per minute

– 25mm aluminum: 40 inches per minute

– 50mm aluminum: 15 inches per minute

Modern systems reduce pierce time by up to 50% compared to older technology, significantly boosting overall productivity for high-volume operations.

Economic Reality: Plasma’s Aluminum Cutting Advantage

Cost Comparison Breakdown

Plasma systems provide substantial cost advantages over lasers for aluminum cutting:

– Initial investment: 30-50% lower than comparable laser systems

– Operating costs: Air plasma costs pennies per cut; even H35 systems run cheaper than lasers

– Consumable life: Modern systems extend electrode/nozzle life through better gas control

– Mixed metal capability: One plasma system handles aluminum, steel, stainless, and copper

ROI Scenarios That Make Sense

General fabrication shops achieve fastest payback with plasma systems handling mixed metals including aluminum. Specialized precision work might justify laser costs, but only when tolerances demand it. For mobile repair operations, portable plasma units provide unmatched practicality for on-site aluminum cutting jobs.

Final Verdict: Plasma cutters absolutely cut aluminum effectively across an impressive thickness range—from thin sheets to 6-inch plates. Match your equipment to your actual needs, select appropriate gases for your quality requirements, and follow basic safety protocols. You’ll produce professional-quality aluminum cuts that rival more expensive processes while maintaining the flexibility to handle other metals in your shop. For most aluminum cutting applications, modern plasma technology delivers the perfect balance of precision, speed, and cost-effectiveness that keeps fabrication shops productive and profitable.