Few DIYers realize that 70% of PVC plumbing failures start with a poorly cut pipe. That slight angle in your sprinkler line or the hidden burr in your drain pipe becomes a guaranteed leak point when pressure builds. Whether you’re installing irrigation or fixing a bathroom sink, mastering your PVC pipe cutter transforms frustrating rework into professional results you can trust. This guide delivers battle-tested techniques used by plumbers to achieve square, smooth cuts every time—saving you hours of headaches and costly repairs.

Crooked cuts happen when beginners rush the process or use the wrong tool for the job. But with the right cutter in your hands and proper technique, you’ll create edges that slide perfectly into fittings without gaps or stress points. By the end of this guide, you’ll know exactly how to select, position, and operate any PVC cutter—even in tight spaces—while avoiding the three critical mistakes that ruin 9 out of 10 DIY plumbing projects.

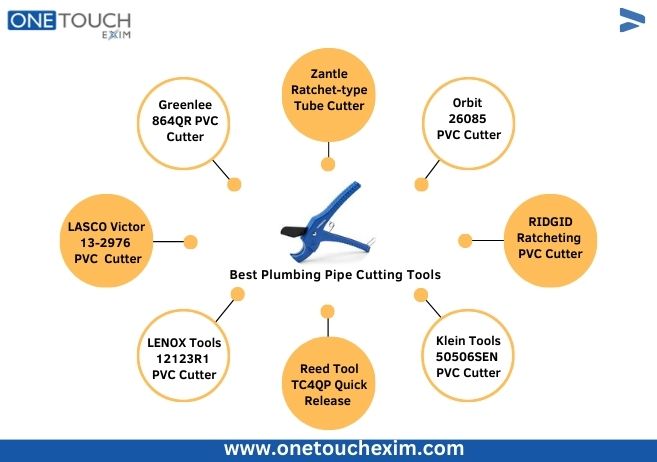

Choose the Right PVC Pipe Cutter for Your Job

Ratcheting Cutters for Effortless Large-Diameter Cuts

Ratcheting cutters conquer 2-inch pipes with minimal hand strain using their gear-driven mechanism. As you squeeze the handles, a hardened steel blade advances incrementally—each cycle biting 1-2mm deeper into the PVC. This controlled pressure prevents pipe crushing, especially crucial in cramped crawl spaces where leverage is limited. Professionals rely on these for irrigation mainlines because the adjustable pipe stop ensures repeatable lengths, and the safety lock prevents accidental closure during transport.

Scissor-Style Cutters for Quick Repairs

When you need to fix a broken sprinkler riser in under a minute, scissor-style cutters deliver speed for ½ to 1-inch pipes. Their curved blades naturally cradle the pipe, but require steady hand pressure throughout the cut. Avoid twisting motions that create oval-shaped ends—instead, position your mark directly under the pivot point and squeeze smoothly until the blades meet. Keep these in your truck for emergency repairs, but skip them for pipes over 1 inch where they risk deformation.

Rotary Cutters for Showroom-Quality Edges

Rotary cutters produce glass-smooth edges essential for visible plumbing runs using a precision cutting wheel that orbits the pipe. Position the wheel directly on your mark, then tighten the tension knob just enough to hear a light scraping sound. Rotate the tool 360 degrees, then advance the knob ¼ turn before the next rotation. Repeat this cycle until the pipe separates cleanly—ideal for display projects where rough edges would look unprofessional.

Essential Safety Setup Before Cutting

Non-Negotiable Safety Gear Checklist

Skip eye protection at your peril. PVC shards fly unpredictably during cuts, making ANSI-rated safety glasses with side shields mandatory—regular prescription glasses won’t stop high-velocity particles. Pair these with cut-resistant gloves to handle razor-sharp edges, and add an N95 mask when cutting indoors to avoid inhaling PVC dust. For floor-level work, kneepads prevent joint damage during extended projects.

Optimize Your Cutting Station in 3 Steps

First, support pipes every 3-4 feet with sawhorses to prevent flexing that causes angled cuts. Second, position bright LED task lighting directly above your mark to eliminate shadows. Third, clear a 3-foot radius around your workspace—PVC pipes can whip violently when severed. Never cut while holding pipe against your body; anchor it securely to avoid injury from sudden movement.

Master the Ratcheting Cutter Technique in 4 Steps

Precision Pipe Positioning

Release the safety lock and open the jaws fully. Slide your marked pipe between the blades until the cut line aligns perfectly with the blade center. The pipe must rest squarely against the adjustable stop—any gap here guarantees a crooked cut. Verify perpendicular alignment by sighting down the pipe from both ends; even a 5-degree tilt will cause leaks under pressure.

Execute the Perfect Ratchet Cycle

Squeeze handles until the blade bites 1-2mm into the PVC surface (you’ll hear a distinct scraping sound). Fully release the handles to reset the mechanism—partial releases wear out the ratchet prematurely. Repeat this cycle while maintaining even pressure, rotating the pipe 90 degrees after every two cycles to distribute force evenly. Stop squeezing when the blade nears the pipe bottom to avoid crushing the final section.

Fix Common Cutting Failures Immediately

Stop Jagged Cuts Before They Happen

Dull blades cause 90% of rough edges. Replace blades when you notice “furry” PVC strands or require excessive force. If cuts turn jagged mid-project, clean residue with PVC cleaner and apply silicone spray lubricant. Crucially, maintain perfect perpendicular alignment—twisting the cutter even slightly creates angled edges that won’t seal in fittings. Secure pipes firmly before cutting to prevent movement-induced imperfections.

Prevent Pipe Crushing in Cold Weather

Cold PVC becomes brittle below 40°F, cracking instead of cutting cleanly. Warm pipes for 30-60 seconds with a heat gun (never direct flame) to restore flexibility. Always apply gradual pressure—let the cutter’s mechanism do the work. If your pipe deforms before cutting, you’re either using an undersized tool or forcing the cut. Downgrade to a smaller diameter pipe or upgrade to industrial-grade PVC for critical projects.

Professional Edge Finishing Techniques

Deburr Like a Master Plumber

Every cut requires deburring to prevent fitting damage and leaks. Use a rotating deburring tool or utility knife to remove inner burrs first—hold the blade at a 10-15 degree angle and rotate the pipe. Then chamfer the outer edge to create a smooth bevel that guides fittings into place. Skip this step, and you’ll force fittings over sharp edges that compromise seals. Finish by wiping the end with PVC primer to eliminate cutting oils.

Verify Cut Quality in 20 Seconds

Hold the cut end against a carpenter’s square—if light shows through any gap, the angle exceeds 1 degree and will leak. Measure final length against your mark; remember you can always trim more but never add material back. Test-fit into a coupling dry before priming—any resistance means burrs remain or the cut isn’t square. Professional plumbers reject cuts requiring force during dry-fit tests.

Maintain Cutters for 10x Longer Life

Daily Care That Prevents Costly Replacements

Wipe blades with a rag dampened in PVC cleaner after every 3-5 cuts to remove sticky residue. Engage the safety lock before storage to protect the blade edge. Store tools in climate-controlled areas—humidity causes rust that ruins blade alignment faster than dulling. During storage, hang cutters by their handles to prevent pressure on the mechanism.

Monthly Deep Maintenance Schedule

Disassemble the ratchet mechanism monthly during heavy use. Blast PVC dust from pivot points with compressed air, then apply rust inhibitor to all metal components. Sharpen or replace blades every 500 cuts—look for nicks or reduced cutting efficiency as warning signs. Test blade tension by cutting scrap pipe; if it requires excessive force, recalibrate per manufacturer instructions.

Advanced Cutting Tactics for Tough Situations

Cut 2+ Inch Pipes Without Crushing

For large-diameter pipes, pre-score the surface with a utility knife along your mark to guide the blade. Warm the pipe gently with a heat gun for 30 seconds to increase flexibility. Make multiple shallow passes instead of forcing a single cut, rotating the pipe 90 degrees after every two ratchet cycles. This distributes pressure evenly and prevents oval-shaped ends that leak at fittings.

Execute Perfect 45-Degree Cuts for Corners

Use a miter box clamped to your workbench for flawless angle cuts. Mark all four sides of the pipe at your desired angle before cutting. Remember: angled cuts shorten the pipe’s effective length—measure ¼ inch longer than your final dimension to compensate. Rotate the cutter steadily around the pipe without wobbling; any deviation creates uneven edges that won’t seal in corner fittings.

Professional Efficiency Hacks

Batch-Cut Pipes Like a Pro in 5 Minutes

Measure and mark all pipes for your project before making the first cut. Create a stop-block jig by clamping a scrap board to your workbench—this ensures identical lengths for multiple runs. Always cut longest pieces first from full pipe lengths to minimize waste. Top plumbers save 30 minutes per project by organizing cuts from longest to shortest.

Select Cutters That Last Through 500+ Projects

Invest in ratcheting cutters with high-carbon steel blades—they stay sharp 3x longer than budget models. Look for ergonomic handles with non-slip grips that reduce hand fatigue during marathon sessions. Avoid plastic components; professional cutters use all-metal construction rated for 4-inch pipes. Expect to pay $40-60 for a tool that won’t fail mid-project, versus $15 models that crack after 20 cuts.

Cut PVC in Optimal Weather Conditions

Work between 40-80°F for clean, predictable cuts—cold pipes shatter, hot pipes deform. In summer, cut early morning before pipes heat up in direct sun. Account for thermal expansion: pipes cut at 90°F will shrink 1/16 inch when cooling to 70°F. For outdoor projects, shade pipes with a tarp for 15 minutes before cutting to stabilize temperature.

Master these techniques, and you’ll create PVC joints that seal permanently under pressure while avoiding the costly mistakes that plague beginners. The right cutter paired with proper technique transforms plumbing from a chore into a precise craft—where every cut fits perfectly and every joint lasts decades. Start applying these methods on your next project, and you’ll save hundreds in replacement parts and emergency plumber calls.